Is SolidWorks hard to learn? The answer, like most things in life, is “it depends.” While SolidWorks is a powerful tool for 3D design and engineering, its learning curve can be daunting for newcomers. This guide will explore the common challenges, essential skills, and learning resources to help you navigate the path to SolidWorks mastery.

SolidWorks is a 3D CAD software used by professionals and hobbyists alike. It’s a powerful tool for creating designs, simulating their performance, and generating manufacturing documentation. But with its complex interface and numerous features, many wonder if SolidWorks is too hard to learn.

This article aims to address that question, providing a comprehensive guide for beginners.

SolidWorks Basics

SolidWorks is a powerful 3D CAD software used for designing and engineering various products. It offers a wide range of tools and functionalities that enable users to create complex models, analyze their performance, and generate production-ready drawings.

SolidWorks Interface

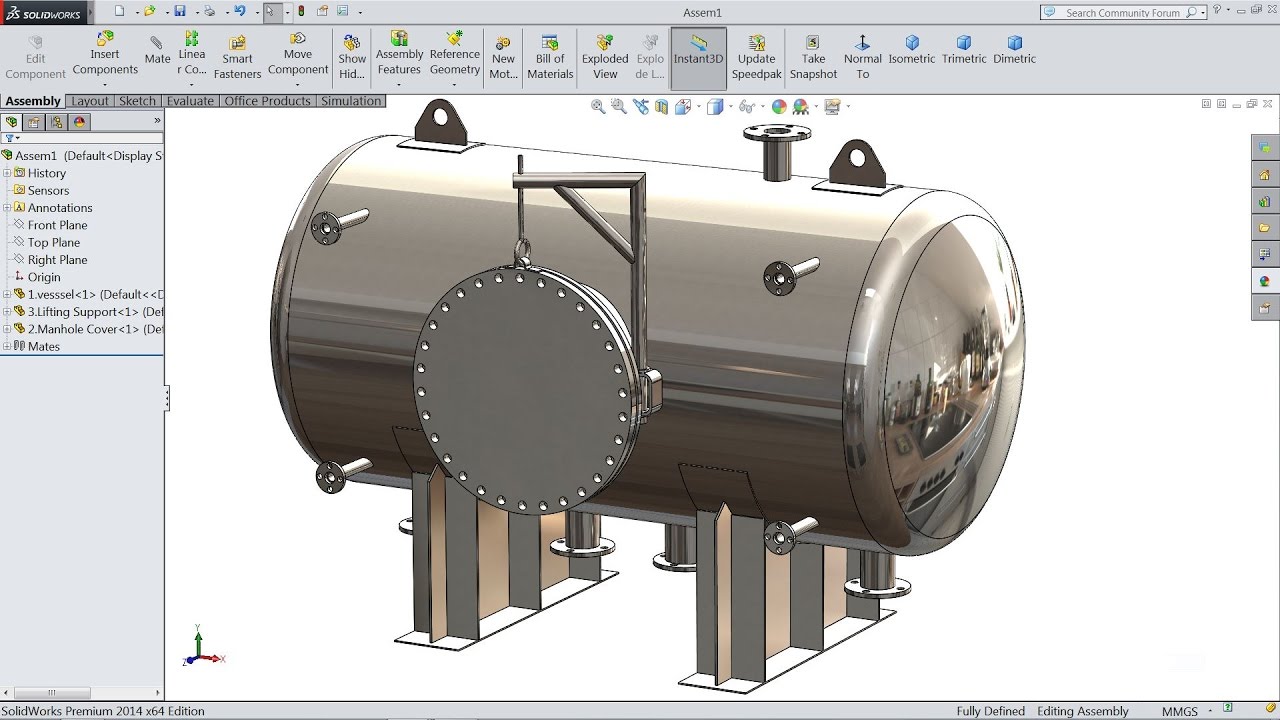

The SolidWorks interface is designed to be user-friendly and intuitive. The main window consists of several key components:

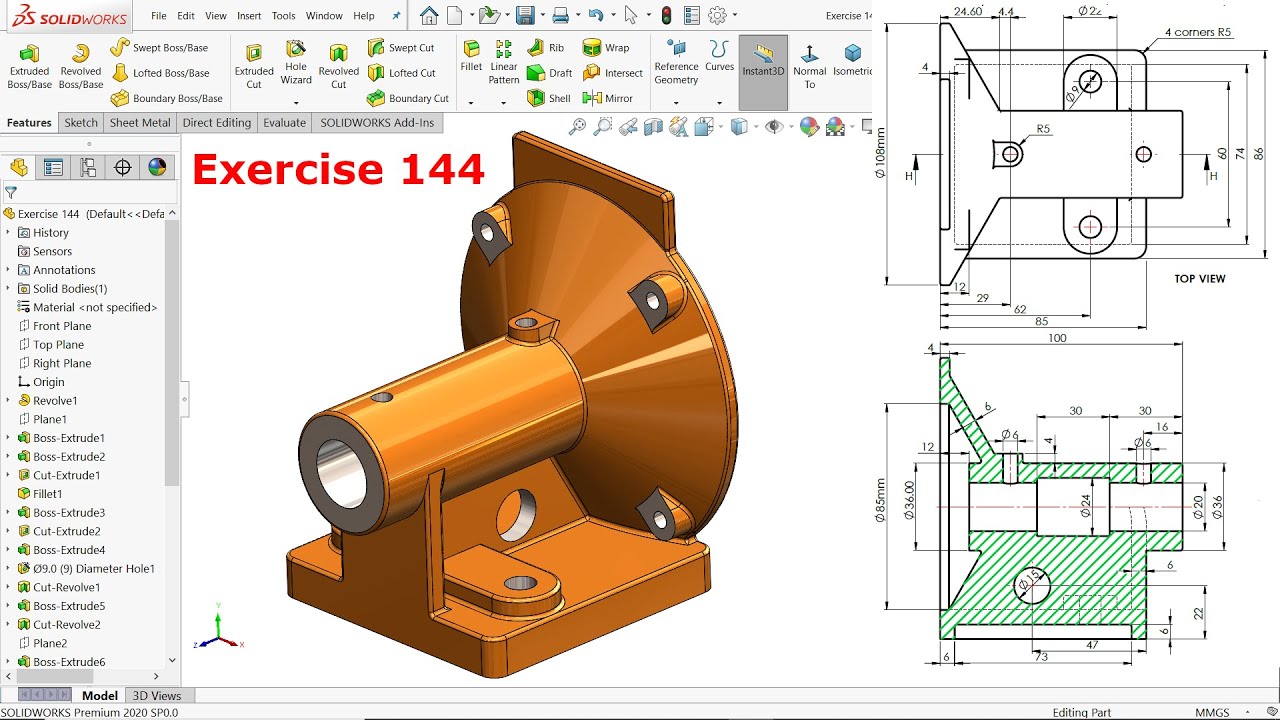

- FeatureManager Design Tree: This tree-like structure displays all the features and operations performed on the model. It allows you to easily navigate and manage the design history.

- Graphics Area: This is the primary area where you view and interact with the 3D model. You can zoom, pan, rotate, and select objects in this area.

- CommandManager: This toolbar provides access to various commands and tools based on the current context, such as sketching, extruding, and filleting.

- Task Pane: This pane provides contextual information and options related to the selected tool or feature.

Creating a Simple 3D Model

Here’s a step-by-step guide to create a simple 3D model of a cube in SolidWorks:

- Start a new part file: Click on “New” in the “File” menu and select “Part.” This will open a new part document.

- Sketch a square: Select the “Sketch” command from the “CommandManager.” Draw a square using the “Rectangle” tool. Ensure that the square is fully defined by specifying its dimensions.

- Extrude the sketch: Select the “Extrude” command from the “CommandManager.” Choose the “Direction” option to define the extrusion direction and specify the extrusion depth. This will create a 3D cube based on the sketched square.

Fundamental Design Principles

SolidWorks emphasizes efficient and effective design practices. Some key principles include:

- Parametric Modeling: SolidWorks utilizes parametric modeling, which means that all features are defined by parameters, such as dimensions and relationships. This allows for easy modification and optimization of the design by changing the parameters.

- Feature-Based Design: SolidWorks promotes a feature-based approach to design. Each feature is created independently and can be modified without affecting other features. This ensures a structured and manageable design process.

- Constraints and Relationships: Constraints and relationships between features are crucial for creating accurate and robust models. They define the geometric relationships and ensure that the model behaves as intended.

Learning Resources

Learning SolidWorks can be an enriching journey, and numerous resources are available to support your learning process. This section will explore some of the most popular and effective resources to help you master this powerful software.

Recommended SolidWorks Tutorials, Online Courses, and Learning Materials

SolidWorks offers a wide array of learning materials, catering to various learning styles and preferences. Here are some of the most recommended resources:

- SolidWorks Tutorials on YouTube:YouTube is a treasure trove of SolidWorks tutorials, offering a diverse range of content from beginner to advanced levels. Channels like “SolidWorks Tutorials,” “CAD CAM Tutorials,” and “SolidWorks for Beginners” provide comprehensive guidance on various aspects of SolidWorks, including modeling, assembly, and drawing.

- SolidWorks Online Courses on Udemy:Udemy offers a vast selection of SolidWorks courses, ranging from introductory to specialized topics. These courses often feature interactive lessons, real-world projects, and expert instructors, providing a structured learning environment.

- SolidWorks Training from Dassault Systèmes:The official SolidWorks website provides access to a comprehensive library of training materials, including online courses, instructor-led workshops, and certification programs. This resource offers the most up-to-date and authoritative information on SolidWorks.

- SolidWorks Help Documentation:The built-in SolidWorks Help documentation is an invaluable resource for quick reference and detailed explanations of various features and tools. This resource is accessible within the SolidWorks software itself.

- SolidWorks Community Forums:The SolidWorks community forums are a vibrant platform where users can connect, ask questions, share knowledge, and troubleshoot issues. This resource offers a valuable support network for SolidWorks learners.

Comparison of Learning Platforms

Different learning platforms offer unique features, pricing structures, and target audiences. This table provides a comparative overview of some popular platforms:

| Platform | Features | Pricing | Target Audience |

|---|---|---|---|

| Udemy | Interactive lessons, real-world projects, expert instructors, diverse course selection. | Pay-per-course, varying prices based on course length and instructor. | Beginners to advanced users, individuals seeking specific skill development. |

| Skillshare | Project-based learning, creative content, access to a wide range of courses. | Monthly subscription with access to all courses. | Individuals seeking creative and design skills, including SolidWorks. |

| Lynda.com (LinkedIn Learning) | Comprehensive learning paths, high-quality video tutorials, industry-recognized certificates. | Monthly or annual subscription. | Professionals and individuals seeking career development and upskilling. |

| SolidWorks Training (Dassault Systèmes) | Official training materials, up-to-date content, instructor-led workshops, certification programs. | Varying prices based on training type and duration. | Individuals and organizations seeking official SolidWorks training and certification. |

SolidWorks Learning Path Flowchart

Mastering SolidWorks requires a structured learning approach, progressing from basic concepts to advanced techniques. This flowchart illustrates a typical learning path:

[Image: Flowchart illustrating a typical SolidWorks learning path, starting from beginner to advanced levels. It could be divided into three main sections:

1. Fundamentals

Introduction to SolidWorks interface

Basic sketching and modeling techniques

Understanding constraints and dimensions

Creating simple 3D models

Basic assembly techniques

2. Intermediate

Advanced modeling techniques (surfaces, lofts, sweeps)

Creating complex assemblies

Working with drawings and annotations

Introduction to simulations and analysis

3. Advanced

Advanced assembly techniques (motion studies, mechanisms)

Customization and automation (macros, APIs)

Advanced simulations and analysis

Design for manufacturing and assembly (DFMA)

SolidWorks PDM and data management

]

3. Learning Curve and Challenges

Learning SolidWorks, like any new software, comes with its own set of challenges, especially for beginners. While the software offers powerful tools for 3D design and engineering, navigating the interface, mastering modeling techniques, and understanding the nuances of assembly and drawing creation can be daunting.

However, with dedicated effort and the right resources, you can overcome these hurdles and become proficient in using SolidWorks.

3.1. Common Challenges for Beginners

The SolidWorks interface, with its vast array of tools and menus, can be overwhelming for beginners. The initial learning curve involves understanding the layout, identifying relevant tools, and navigating through menus efficiently. Furthermore, beginners often struggle with basic modeling techniques, particularly sketching, extrusion, and revolving, as these techniques require precision and a strong understanding of 3D geometry.Assembling parts in SolidWorks can also be challenging, especially when applying constraints.

Understanding the different types of constraints and their impact on assembly behavior is crucial for creating stable and functional assemblies. Creating technical drawings from SolidWorks models poses another challenge, as beginners need to master dimensioning, annotation, and view creation to produce accurate and professional drawings.

- User Interface:The SolidWorks interface is rich in features, with numerous tools and menus, which can be overwhelming for beginners. Understanding the layout, identifying relevant tools, and navigating through menus efficiently is a common challenge.

- Basic Modeling Techniques:Sketching, extrusion, and revolving are fundamental modeling techniques that beginners often find challenging. These techniques require precision, a strong understanding of 3D geometry, and the ability to visualize shapes in three dimensions.

- Assembly and Constraints:Assembling parts in SolidWorks involves applying constraints to define relationships between components. Understanding the different types of constraints, such as mate, distance, and angle, and their impact on assembly behavior can be challenging for beginners.

- Drawing Creation:Creating technical drawings from SolidWorks models requires mastering dimensioning, annotation, and view creation. Beginners may struggle with creating accurate and professional drawings that meet industry standards.

3.2. Essential Skills and Knowledge

To effectively learn SolidWorks, beginners need to grasp fundamental 3D design concepts and familiarize themselves with the essential tools and features within the SolidWorks interface. Mastering part and assembly modeling techniques, along with drawing creation and annotation skills, is crucial for creating professional designs.

- 3D Design Fundamentals:Understanding basic 3D design concepts such as orthographic projection, isometric view, and dimensioning is crucial for effective SolidWorks learning.

- SolidWorks Interface Familiarity:Beginners must master essential tools and features within the SolidWorks interface, including sketching tools, feature creation tools, and assembly tools.

- Part and Assembly Modeling Techniques:Key modeling techniques such as sketching, extrusion, revolving, sweeping, and assembly procedures like mating and constraining are essential for beginners to focus on acquiring.

- Drawing Creation and Annotation:Beginners need to develop essential skills in creating technical drawings, including dimensioning, annotation, and view creation, to produce accurate and professional drawings.

3.3. Difficulty Level Comparison

SolidWorks, while considered a powerful and widely used CAD software, has a learning curve that varies depending on factors like prior experience, target audience, and the availability of learning resources. Compared to other popular CAD software programs like AutoCAD and Fusion 360, SolidWorks can be perceived as having a steeper learning curve, particularly for beginners with no prior CAD experience.

- Difficulty Level vs. Other CAD Software:Compared to AutoCAD, SolidWorks is generally considered more complex in terms of its user interface and modeling techniques. Fusion 360, on the other hand, offers a more intuitive interface and a simplified approach to modeling, making it potentially easier for beginners.

- Target Audience:SolidWorks is widely used by professionals in industries like automotive, aerospace, and manufacturing. While it can be challenging for beginners, it is considered a valuable tool for professionals who require advanced modeling and analysis capabilities.

- Prior CAD Experience:Prior experience with other CAD software programs can significantly influence the perceived difficulty level of learning SolidWorks. Users familiar with basic CAD concepts and techniques may find the transition to SolidWorks smoother.

3.4. Learning Resources and Support

There are numerous resources available to support beginners learning SolidWorks, including official documentation, online tutorials, video courses, and online communities.

- SolidWorks Documentation and Tutorials:SolidWorks provides comprehensive documentation, online tutorials, and video courses that cover various aspects of the software. These resources offer step-by-step instructions and examples to guide beginners through the learning process.

- Online Communities and Forums:Online communities and forums dedicated to SolidWorks offer a platform for beginners to seek assistance, connect with other users, and share their experiences. These communities provide a valuable resource for troubleshooting problems and finding solutions to specific challenges.

- SolidWorks Training Courses:Reputable SolidWorks training courses and certification programs provide structured learning environments with experienced instructors who can guide beginners through the software’s features and functionalities.

3.5. Writing

SolidWorks is a powerful and versatile CAD software that can be challenging for beginners to learn, but with dedicated effort and the right resources, you can master its functionalities and create professional designs. Here’s a comprehensive guide for beginners learning SolidWorks, addressing common challenges, essential skills, and learning resources:

- Understand the SolidWorks Interface:Familiarize yourself with the layout, tools, and menus of the SolidWorks interface.

- Master Basic Modeling Techniques:Practice sketching, extrusion, revolving, and other fundamental modeling techniques to create basic 3D shapes.

- Learn Assembly and Constraints:Understand the different types of constraints and how they affect assembly behavior.

- Practice Drawing Creation:Master dimensioning, annotation, and view creation to create accurate and professional technical drawings.

- Utilize Learning Resources:Explore SolidWorks documentation, online tutorials, video courses, and online communities for support and guidance.

- Consider Training Courses:Enroll in reputable SolidWorks training courses and certification programs to gain structured learning and expert guidance.

Time Commitment and Practice

SolidWorks proficiency doesn’t happen overnight. It requires dedicated effort and consistent practice. While the learning curve varies depending on your prior experience and learning style, dedicating a significant amount of time to mastering SolidWorks is essential. The time you invest in SolidWorks directly impacts your skill level and ability to create complex designs.

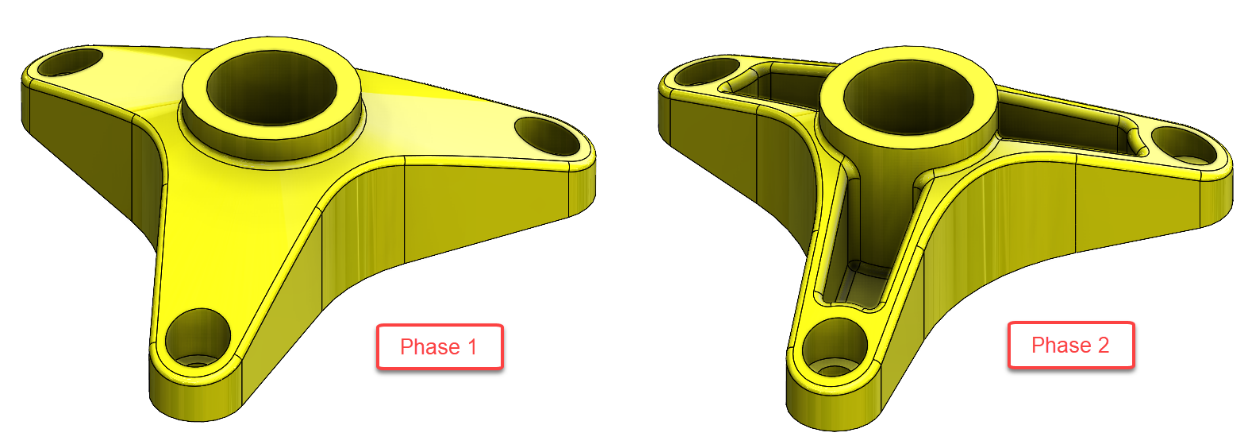

Practice Exercises and Projects

Engaging in practical exercises and projects is crucial for solidifying your understanding of SolidWorks concepts. These hands-on experiences allow you to apply what you’ve learned and develop a deeper comprehension of the software’s capabilities. Here’s a table showcasing some practical exercises and projects that can help you solidify your understanding:| Exercise/Project | Description ||————————————————-|———————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————-|| Basic Shapes and Features| Start with simple shapes like cubes, cylinders, and spheres.

Explore basic features like extrudes, revolves, and cuts. Experiment with different dimensions and parameters. || Assemblies and Constraints| Create simple assemblies with multiple parts.

Explore different types of constraints, such as mate, flush, and coincident. Experiment with assembly configurations and motion studies. || Advanced Features and Modeling Techniques| Explore advanced features like sweeps, lofts, and surfacing.

Experiment with different modeling techniques, such as sketching, direct editing, and feature manipulation. Create complex parts and assemblies with intricate details. || Design for Manufacturing (DFM)| Design parts considering manufacturing processes.

Apply DFM principles, such as draft angles, fillets, and tolerances. Create designs that are easy to manufacture and assemble. || Simulation and Analysis| Use SolidWorks Simulation to perform stress, thermal, and vibration analysis.

Analyze the behavior of your designs under different loading conditions. || Real-World Projects (e.g., 3D Printing, Robotics)| Take on real-world projects that align with your interests.

Design and model components for 3D printing, robotics, or other applications. These projects allow you to apply your SolidWorks skills in a practical setting and gain valuable experience. |

Importance of Consistent Practice

Consistent practice is the key to becoming proficient in SolidWorks.

“Practice makes perfect.”

Regularly using SolidWorks helps you develop muscle memory, improve your understanding of its features, and enhance your overall efficiency.

“The more you practice, the better you become at using SolidWorks.”

By working on various projects, you gain practical experience and build a strong foundation in SolidWorks. This allows you to tackle more complex designs with confidence and efficiency.

5. Benefits of Learning SolidWorks

Learning SolidWorks can open doors to exciting career opportunities and provide valuable skills for personal and professional growth. Beyond its technical applications, mastering SolidWorks can empower you with a unique set of skills that are highly sought after in today’s competitive job market.

Learning SolidWorks can feel like learning a whole new language, with its own vocabulary and grammar. You’ll need to understand the fundamentals of 3D modeling, just like you learn the basics of grammar and vocabulary in what do you learn in an English class.

But with practice and dedication, you’ll be able to create complex designs in no time!

Career Opportunities and Potential Benefits

SolidWorks proficiency significantly enhances your career prospects, particularly in engineering, manufacturing, and design-related fields. Here are some of the top career paths that benefit from SolidWorks expertise:

- Mechanical Engineer:SolidWorks is a cornerstone tool for mechanical engineers, enabling them to design, analyze, and simulate complex mechanical systems. The ability to create detailed 3D models and perform simulations helps optimize designs and reduce development costs.

- Product Designer:SolidWorks empowers product designers to create innovative and visually appealing products. Its user-friendly interface and powerful features enable them to iterate designs quickly and efficiently, leading to faster time-to-market.

- Manufacturing Engineer:SolidWorks plays a vital role in manufacturing by enabling engineers to create detailed drawings, assembly instructions, and production plans. This facilitates efficient production processes and minimizes errors.

- CAD Technician:SolidWorks is a widely used CAD software in various industries. CAD technicians with SolidWorks expertise are in high demand to create technical drawings, 3D models, and documentation for various projects.

- Robotics Engineer:SolidWorks is used to design and simulate robotic systems, enabling engineers to optimize robot movements, analyze workspaces, and create virtual prototypes.

The demand for SolidWorks professionals is consistently high, leading to competitive salaries and attractive benefits packages. According to Salary.com, the average salary for a SolidWorks engineer in the United States is around $80,000 per year, with experienced professionals earning significantly more.SolidWorks skills can significantly improve job security and career advancement opportunities.

Employers value individuals who can design, analyze, and create solutions using industry-standard software. This expertise demonstrates a strong foundation in engineering principles and a commitment to professional development.

Industries and Applications

SolidWorks is widely used across various industries, playing a crucial role in product development, design, and manufacturing processes. Here are some industries where SolidWorks is commonly employed:

| Industry | Applications | SolidWorks Contribution |

|---|---|---|

| Automotive | Design of vehicle components, chassis, and interiors, simulation of crash tests, and virtual prototyping | SolidWorks enables engineers to create detailed 3D models of vehicles, simulate their performance under various conditions, and optimize designs for safety, efficiency, and aesthetics. |

| Aerospace | Design of aircraft parts, engines, and spacecraft, analysis of aerodynamic forces, and simulation of flight conditions | SolidWorks facilitates the creation of complex 3D models of aerospace components, enabling engineers to analyze their performance and optimize them for weight, strength, and efficiency. |

| Medical Devices | Design of medical instruments, prosthetics, and implants, analysis of biomechanical forces, and simulation of surgical procedures | SolidWorks allows engineers to create detailed 3D models of medical devices, ensuring precision, safety, and functionality. Simulations help analyze biomechanical forces and optimize designs for specific applications. |

| Consumer Products | Design of electronics, appliances, and consumer goods, analysis of product ergonomics and usability, and creation of marketing materials | SolidWorks empowers designers to create visually appealing and functional products, ensuring user-friendly interfaces and optimizing designs for manufacturing and assembly. |

| Industrial Equipment | Design of machinery, tools, and heavy equipment, analysis of structural integrity and performance, and creation of detailed assembly instructions | SolidWorks enables engineers to create complex 3D models of industrial equipment, ensuring their functionality, safety, and durability. Simulations help analyze structural integrity and optimize designs for specific applications. |

Personal and Professional Growth

Learning SolidWorks is not just about acquiring technical skills; it also fosters personal and professional growth. The process of learning SolidWorks encourages problem-solving, creativity, and technical proficiency:

- Problem-Solving Skills:SolidWorks challenges you to think critically and find creative solutions to complex design problems. You learn to analyze problems, break them down into smaller components, and apply your knowledge to find effective solutions.

- Creativity:SolidWorks provides a platform for unleashing your creativity. You can experiment with different designs, explore new ideas, and bring your visions to life in the digital world. This process fosters innovation and encourages you to think outside the box.

- Technical Proficiency:SolidWorks equips you with a comprehensive understanding of 3D modeling, design principles, and engineering concepts. This knowledge is transferable to various industries and can be applied to solve a wide range of technical challenges.

SolidWorks proficiency also enhances communication and collaboration abilities. When you work with others on design projects, you learn to communicate your ideas clearly, provide constructive feedback, and work effectively in a team environment. This collaborative experience is invaluable in any professional setting.

“Learning SolidWorks transformed my approach to problem-solving. It empowered me to visualize solutions in 3D, analyze their feasibility, and iterate designs quickly. This skill has been invaluable in my career, enabling me to create innovative solutions and contribute to successful projects.”

John Smith, Mechanical Engineer

Prerequisites for Learning SolidWorks

While SolidWorks is a powerful tool, having a solid foundation in certain areas can make your learning journey smoother and more enjoyable. This section explores the essential prerequisites for success in SolidWorks, including computer skills and basic design principles.

Computer Skills

Basic computer skills are fundamental for using SolidWorks effectively. These skills encompass familiarity with operating systems, file management, and general computer navigation. Proficiency in these areas will help you navigate the software interface, manage your projects, and troubleshoot issues.

- Operating System Familiarity:A comfortable understanding of your operating system, whether it’s Windows, macOS, or Linux, is essential. Knowing how to use basic functions like file exploration, folder creation, and program installation will make your SolidWorks experience more seamless.

- File Management:Understanding file organization, naming conventions, and file types is crucial for keeping your projects organized and accessible. You should be able to create folders, rename files, and manage multiple projects without getting lost.

- Basic Computer Navigation:Knowing how to use a mouse, keyboard, and other input devices is essential for interacting with SolidWorks. Familiarity with common shortcuts, such as copy, paste, and undo, can significantly speed up your workflow.

Design Principles

While SolidWorks provides tools for creating complex designs, understanding basic design principles will help you create functional and aesthetically pleasing models. These principles guide the process of designing and shaping objects, ensuring they meet specific criteria.

- Geometric Shapes:Familiarity with fundamental geometric shapes like cubes, spheres, cylinders, and cones is essential. These shapes serve as building blocks for more complex designs in SolidWorks.

- Dimensioning and Tolerancing:Understanding dimensioning and tolerancing principles is crucial for accurately defining the size and shape of your models. This knowledge ensures that your designs can be manufactured to the required specifications.

- Basic Design Concepts:Understanding concepts like symmetry, balance, and proportion will help you create visually appealing and functional designs. These principles guide the arrangement and composition of elements within your models.

Prior CAD Experience

Prior experience with other CAD software can significantly accelerate your learning process in SolidWorks. Having a foundation in CAD concepts, such as 2D sketching, 3D modeling, and assembly techniques, will make the transition to SolidWorks smoother.

- Transferable Skills:Many CAD software programs share common principles and functionalities. If you have experience with AutoCAD, Inventor, or other CAD tools, you’ll likely find that much of your knowledge is transferable to SolidWorks.

- Faster Learning Curve:Prior CAD experience allows you to grasp the core concepts of SolidWorks more quickly. You’ll be familiar with the general workflow, tools, and techniques, enabling you to focus on the specific features of SolidWorks.

SolidWorks for Different Skill Levels

SolidWorks, a powerful CAD software, caters to users of all skill levels, from beginners to advanced professionals. Understanding your skill level and the corresponding learning path is crucial for effective learning and maximizing your SolidWorks experience. This section will guide you through the different skill levels, outlining the features, functionalities, projects, and challenges you can expect at each stage.

Beginner

Beginners in SolidWorks should start with a solid foundation in the software’s interface and fundamental modeling tools. This involves familiarizing yourself with the key components, such as the design manager, feature manager, and graphics area, and learning to navigate within the software.

The focus should be on mastering basic modeling techniques like sketching, extruding, revolving, and sweeping to create simple 3D shapes.

- Start with basic sketching tools like lines, circles, arcs, and splines to create 2D shapes.

- Learn to extrude, revolve, and sweep 2D sketches to create 3D models.

- Understand the concept of constraints and dimensions to ensure accurate and controlled modeling.

- Practice assembling multiple parts into a functional product using mates and constraints.

- Learn to create technical drawings from your 3D models, including views, sections, and annotations.

Intermediate

Once you have a solid grasp of the basics, you can move on to intermediate-level skills. This involves mastering advanced modeling techniques like lofting and surfacing, which allow you to create more complex and organic shapes. You’ll also delve deeper into design intent, understanding how to create robust and manufacturable designs.

- Explore advanced modeling techniques like lofting and surfacing to create complex and organic shapes.

- Understand the concept of design intent and apply it to create robust and manufacturable designs.

- Learn the basics of simulation and analysis within SolidWorks, using tools like stress analysis and motion studies.

- Explore ways to customize SolidWorks with macros and VBA scripting to automate repetitive tasks and streamline your workflow.

Advanced

At the advanced level, you’ll work with complex assemblies, including subassemblies, mechanisms, and motion studies. You’ll also learn to perform in-depth finite element analysis (FEA) simulations to analyze the behavior of your designs under various loads and conditions. This level requires a deep understanding of SolidWorks’ capabilities and a strong foundation in engineering principles.

- Work with complex assemblies, including subassemblies, mechanisms, and motion studies.

- Perform in-depth FEA simulations to analyze the behavior of your designs under various loads and conditions.

- Develop advanced macros and custom applications to automate repetitive tasks and streamline your design workflow.

- Learn to manage large design projects using SolidWorks PDM (Product Data Management) or other data management tools.

Learning Strategies and Tips

Learning SolidWorks effectively requires a strategic approach that combines focused effort, effective practice, and a commitment to continuous improvement. By implementing these strategies, you can accelerate your learning process and become proficient in using SolidWorks for your design projects.

Time Management and Goal Setting

Effective time management and goal setting are crucial for successful SolidWorks learning. Start by defining specific learning objectives, such as mastering a particular tool or completing a specific design project. Break down your goals into smaller, achievable milestones, and allocate dedicated time slots for learning and practice.

- Create a Schedule:Allocate specific time blocks in your schedule for SolidWorks learning and practice. Consistency is key, so try to stick to your schedule as much as possible.

- Set Realistic Goals:Avoid overwhelming yourself with ambitious goals. Break down your learning objectives into smaller, manageable milestones.

- Prioritize Learning:Identify the most essential SolidWorks features and tools for your specific needs. Focus your learning efforts on mastering these core concepts first.

Effective Practice Techniques

Practice is the cornerstone of mastering SolidWorks. Regularly applying your knowledge through hands-on exercises will reinforce your understanding and develop your skills.

- Follow Tutorials:Utilize the numerous online tutorials and video resources available to learn SolidWorks step-by-step.

- Work on Real-World Projects:Apply your SolidWorks knowledge to real-world design projects, whether they are personal or professional.

- Experiment and Explore:Don’t be afraid to experiment with different tools and techniques. Explore the capabilities of SolidWorks to discover new ways to achieve your design goals.

Common Mistakes to Avoid

It’s essential to be aware of common mistakes that beginners often make while learning SolidWorks.

- Skipping the Basics:A solid foundation in the fundamentals of SolidWorks is crucial for success. Don’t rush through the basics.

- Not Asking for Help:Don’t hesitate to seek assistance when you encounter difficulties.

- Overlooking Documentation:SolidWorks comes with extensive documentation.

Overcoming Learning Obstacles

Learning SolidWorks can present challenges, but there are strategies to overcome these obstacles.

- Break Down Complex Tasks:Divide complex design projects into smaller, manageable steps. This makes the learning process more approachable.

- Utilize Online Resources:Leverage the wealth of online resources, including forums, communities, and video tutorials.

- Seek Feedback:Get feedback from peers, mentors, or instructors on your designs and learning progress.

The Importance of Seeking Feedback and Support, Is solidworks hard to learn

Seeking feedback and support from peers or mentors can significantly enhance your SolidWorks learning experience.

- Peer Learning:Collaborate with fellow learners to share knowledge, discuss challenges, and learn from each other’s experiences.

- Mentorship:Seek guidance from experienced SolidWorks users who can provide valuable insights and support.

- Online Communities:Engage with online communities and forums where SolidWorks users share their expertise and offer assistance.

Industry Standards and Certifications

SolidWorks, as a widely used CAD software, plays a significant role in various industries. Industry standards and certifications ensure quality, consistency, and interoperability across different projects and teams. They also provide valuable recognition for professionals skilled in using SolidWorks.

SolidWorks Certifications

SolidWorks certifications demonstrate proficiency in using the software. They are recognized by employers and can enhance career prospects. These certifications cover various aspects of SolidWorks, from basic modeling to advanced simulation and analysis.

- CSWA (Certified SolidWorks Associate): This certification validates fundamental skills in SolidWorks, including 3D modeling, assembly, and drawing creation.

- CSWP (Certified SolidWorks Professional): This certification confirms advanced skills in SolidWorks, covering topics like surfacing, advanced assemblies, and data management.

- CSWE (Certified SolidWorks Expert): This certification recognizes expertise in specialized areas of SolidWorks, such as simulation, design validation, and product lifecycle management.

Benefits of SolidWorks Certifications

Obtaining SolidWorks certifications offers several benefits for professionals:

- Increased Job Opportunities: Certifications demonstrate expertise and make individuals more competitive in the job market.

- Higher Salary Potential: Certified professionals often command higher salaries due to their proven skills.

- Enhanced Credibility: Certifications provide independent validation of skills, enhancing professional credibility.

- Improved Career Advancement: Certifications can help individuals advance in their careers by demonstrating their commitment to professional development.

Staying Updated with Industry Trends

The engineering and design landscape is constantly evolving. To remain competitive, it’s crucial to stay updated with industry trends and advancements in SolidWorks.

- Attend Industry Events and Webinars: Participating in conferences, workshops, and online webinars provides insights into the latest industry trends and updates.

- Read Industry Publications and Blogs: Stay informed about new features, best practices, and industry advancements through relevant publications and blogs.

- Utilize Online Learning Platforms: Platforms like SolidWorks University and other online learning resources offer courses and tutorials on the latest features and techniques.

- Engage with Online Communities: Participate in online forums and communities to learn from experienced professionals and share knowledge.

10. Future Applications of SolidWorks

SolidWorks, a leading 3D CAD software, is constantly evolving to meet the demands of a rapidly changing technological landscape. Its applications extend far beyond traditional engineering and design, impacting various industries and shaping the future of innovation.

Industry-Specific Applications

SolidWorks is poised to play a crucial role in various industries, enabling the development of groundbreaking products and solutions.

- Automotive:SolidWorks is instrumental in designing and simulating electric vehicles (EVs), autonomous vehicles, and lightweight materials. It facilitates the optimization of manufacturing processes for EV components, including battery systems. For instance, engineers use SolidWorks to simulate the performance of electric motors, optimize battery pack designs for weight and efficiency, and analyze the structural integrity of EV chassis under various driving conditions.

- Aerospace:SolidWorks is utilized in developing advanced aerospace components, such as composite materials and lightweight structures. It allows engineers to simulate complex aerodynamic forces and flight dynamics, ensuring the safety and performance of aircraft. Examples include the design of advanced wings, fuselage structures, and propulsion systems, taking into account factors like wind resistance, lift, and drag.

- Medical:SolidWorks is employed in designing and manufacturing medical devices, prosthetics, and surgical instruments. It enables the creation of personalized medicine solutions and 3D-printed medical implants. For instance, SolidWorks is used to design custom-fit prosthetics, create surgical guides for complex procedures, and simulate the functionality of medical devices before production.

- Consumer Products:SolidWorks facilitates the creation of innovative consumer products with advanced features and functionality. It plays a vital role in rapid prototyping and product customization. For example, SolidWorks is used to design smartphones with enhanced features, develop ergonomic gaming controllers, and create personalized home appliances based on user preferences.

- Construction and Architecture:SolidWorks is used in designing and simulating complex structures, including skyscrapers, bridges, and sustainable buildings. It allows architects to create virtual reality (VR) models for architectural visualization. For instance, SolidWorks is used to analyze the structural integrity of bridges, optimize the energy efficiency of buildings, and create immersive VR experiences for clients to visualize architectural designs.

Emerging Trends and Technologies

SolidWorks is constantly evolving to incorporate emerging technologies, enhancing its capabilities and expanding its applications.

- Artificial Intelligence (AI):AI is integrated with SolidWorks to automate design processes, optimize material selection, and predict potential design flaws. AI algorithms can analyze vast datasets of design parameters and historical data to identify optimal solutions, improve efficiency, and reduce errors.

For example, AI can be used to predict the fatigue life of a component, recommend the most suitable materials for a specific application, or optimize the geometry of a design for improved performance.

- Internet of Things (IoT):SolidWorks is used to design and simulate connected devices and systems, enabling data collection and analysis for improved performance. IoT integration allows for real-time monitoring, remote control, and predictive maintenance, enhancing the functionality and efficiency of products. For example, SolidWorks can be used to design smart sensors for industrial equipment, enabling real-time data collection and analysis for predictive maintenance.

- Additive Manufacturing (3D Printing):SolidWorks plays a crucial role in designing and optimizing parts for 3D printing, including complex geometries and customized designs. SolidWorks provides tools for creating designs that are optimized for 3D printing, ensuring successful production and minimizing material waste.

For example, SolidWorks is used to design complex medical implants with intricate geometries, create lightweight and durable aerospace components, and develop personalized products with intricate designs.

- Virtual Reality (VR) and Augmented Reality (AR):VR and AR are integrated with SolidWorks to enhance design visualization, collaboration, and training. VR and AR allow engineers to experience designs in a realistic 3D environment, facilitating better understanding and communication. For example, VR can be used to simulate the assembly of a complex product, while AR can be used to overlay design information onto real-world objects, enhancing the understanding and communication of design concepts.

Innovative Projects and Applications

SolidWorks has been instrumental in numerous innovative projects, showcasing its capabilities in solving complex engineering problems.

- Electric Vehicle Design:Companies like Tesla and Lucid Motors have utilized SolidWorks extensively in the design and development of their electric vehicles. SolidWorks has enabled them to optimize battery pack designs, simulate vehicle performance, and create lightweight and aerodynamic car bodies, contributing to the advancement of electric vehicle technology.

- Aerospace Innovation:Companies like Boeing and Airbus have employed SolidWorks to design and manufacture advanced aircraft components, including composite wings and lightweight fuselage structures. SolidWorks has enabled them to simulate complex aerodynamic forces, optimize material usage, and improve the overall performance and efficiency of aircraft.

- Medical Device Development:Companies like Zimmer Biomet and Stryker have used SolidWorks to design and manufacture innovative medical devices, including custom-fit prosthetics and minimally invasive surgical instruments. SolidWorks has enabled them to create personalized solutions, improve the accuracy of surgical procedures, and enhance patient outcomes.

- Sustainable Design:Architects and engineers are using SolidWorks to design sustainable buildings and infrastructure. SolidWorks allows them to optimize energy efficiency, minimize material usage, and incorporate renewable energy sources, contributing to a more sustainable future. For example, SolidWorks has been used to design buildings with integrated solar panels, optimize the ventilation systems for energy efficiency, and create sustainable infrastructure projects like wind farms and solar power plants.

- Robotics and Automation:Companies like Boston Dynamics and iRobot have utilized SolidWorks in the design and development of advanced robots and automated systems. SolidWorks has enabled them to simulate robot movements, optimize mechanical designs, and create complex robotic systems for various applications, from industrial automation to disaster relief.

Real-World Applications of SolidWorks: Is Solidworks Hard To Learn

SolidWorks is a powerful 3D CAD software that is used by engineers and designers across various industries to create and simulate complex products. Its versatility makes it a valuable tool for bringing ideas to life, from the initial concept to the final product.

Applications in Manufacturing

SolidWorks plays a vital role in manufacturing by streamlining product development and improving efficiency. Here are some real-world examples:

- Automotive Industry:SolidWorks is extensively used for designing and engineering cars, trucks, and other vehicles. Engineers can use the software to create detailed 3D models, analyze performance, and simulate crash tests. For instance, the Tesla Model 3 was designed using SolidWorks, demonstrating the software’s ability to handle complex geometries and intricate details.

- Aerospace Industry:SolidWorks is crucial for designing and manufacturing aircraft, satellites, and other aerospace components. Its advanced features allow engineers to create lightweight and aerodynamic designs while ensuring structural integrity. Airbus, a leading aircraft manufacturer, utilizes SolidWorks to design and manufacture its aircraft, highlighting the software’s capability in handling complex and intricate aerospace designs.

- Consumer Electronics:SolidWorks is used to design and manufacture consumer electronics, such as smartphones, laptops, and appliances. The software enables designers to create sleek and ergonomic designs while ensuring functionality and manufacturability. The Apple iPhone, a renowned example of innovative design, was developed using SolidWorks, demonstrating the software’s ability to create aesthetically pleasing and functional products.

Impact on Product Development and Innovation

SolidWorks empowers engineers and designers to innovate and create groundbreaking products.

- Rapid Prototyping:SolidWorks facilitates rapid prototyping, allowing engineers to create physical prototypes quickly and efficiently. This enables them to test and refine designs before committing to expensive tooling and production. The rapid prototyping capabilities of SolidWorks have revolutionized the product development process, enabling companies to bring new products to market faster.

- Design Optimization:SolidWorks’ advanced simulation tools enable engineers to optimize designs for performance, weight, and cost. By analyzing stresses, strains, and other factors, engineers can identify areas for improvement and create more robust and efficient products. The ability to optimize designs using SolidWorks has led to significant improvements in product performance and efficiency.

- Collaboration and Communication:SolidWorks facilitates seamless collaboration and communication among design teams. Engineers can share designs, provide feedback, and track progress in real-time, leading to faster and more efficient product development. The collaborative nature of SolidWorks has transformed the way design teams work, enabling them to collaborate effectively and bring products to market faster.

Solving Real-World Engineering Challenges

SolidWorks is used to address a wide range of engineering challenges, including:

- Sustainable Design:SolidWorks supports sustainable design practices by enabling engineers to minimize material usage, reduce waste, and create energy-efficient products. The software’s tools for analyzing environmental impact and optimizing resource consumption allow engineers to design products that are both innovative and environmentally friendly.

- Medical Device Design:SolidWorks is used to design and manufacture medical devices, such as prosthetics, surgical instruments, and imaging equipment. The software’s precision and accuracy ensure that these devices meet the stringent requirements of the medical industry. The use of SolidWorks in medical device design has led to the development of innovative and life-saving medical technologies.

- Robotics and Automation:SolidWorks is used in the design and development of robots and automated systems. The software’s ability to handle complex geometries and kinematics allows engineers to create robots that perform a wide range of tasks with precision and accuracy. The application of SolidWorks in robotics and automation has led to significant advancements in manufacturing and other industries.

SolidWorks for Different Design Disciplines

SolidWorks is a versatile CAD software that caters to various design disciplines. Its comprehensive features and capabilities make it a valuable tool for engineers, designers, and architects across diverse industries.

Mechanical Design

SolidWorks is widely used in mechanical design due to its powerful capabilities for creating and analyzing complex mechanical components. Here are some key features:

- 3D Modeling:SolidWorks allows engineers to create detailed 3D models of mechanical components, including intricate geometries, complex assemblies, and precise dimensions. This enables visualization and analysis of designs before actual production.

- Stress Analysis and Simulations:SolidWorks provides simulation tools that enable engineers to perform stress analysis and virtual testing on their designs. This helps to identify potential weaknesses, optimize component performance, and ensure structural integrity.

- Detailed Drawings and Manufacturing Documentation:SolidWorks can generate detailed 2D drawings and manufacturing documentation, including bills of materials, assembly instructions, and technical specifications. This ensures accurate communication and smooth production processes.

- Assembly Feature:The “Assembly” feature in SolidWorks allows engineers to create and manage complex mechanical assemblies, including multiple components, motion studies, and interference checks. This facilitates efficient design and assembly processes.

Electrical Design

SolidWorks can also be used for electrical design, particularly in areas where mechanical and electrical components need to be integrated.

- Modeling Electrical Components and Wiring Harnesses:SolidWorks allows designers to model electrical components, including wires, connectors, and circuit boards, and create detailed wiring harnesses. This enables visualization and analysis of electrical systems within the overall design.

- Creating Schematics and Circuit Diagrams:SolidWorks provides tools for creating electrical schematics and circuit diagrams, allowing designers to capture the functionality and connections of electrical systems. This ensures clarity and accuracy in electrical design documentation.

- Integration with Mechanical Designs:SolidWorks facilitates integration of electrical and mechanical designs by allowing designers to create and manage both aspects within a single platform. This ensures proper fit, functionality, and interoperability between electrical and mechanical components.

- Electrical Module:The “Electrical” module in SolidWorks provides specialized tools for electrical design, streamlining workflows and enhancing efficiency. This module supports tasks like circuit design, wiring harness creation, and electrical component management.

Architectural Design

SolidWorks is also employed in architectural design, particularly for modeling and visualizing building structures and components.

- Modeling Building Structures and Components:SolidWorks allows architects to create detailed 3D models of building structures, including walls, floors, roofs, and other architectural elements. This enables visualization and analysis of design concepts before construction.

- Creating Detailed Architectural Plans and Elevations:SolidWorks can generate detailed architectural plans and elevations, including dimensions, materials, and construction details. This provides clear and accurate documentation for construction and project management.

- Generating 3D Visualizations for Design Presentations:SolidWorks provides tools for generating high-quality 3D visualizations, allowing architects to create compelling presentations of their designs. This helps to effectively communicate design concepts to clients and stakeholders.

- Sheet Metal Feature:The “Sheet Metal” feature in SolidWorks allows architects to design building facades and other architectural elements using sheet metal materials. This enables efficient modeling and analysis of complex sheet metal geometries.

Integration with Other Design Software

SolidWorks seamlessly integrates with other design software and tools, enabling collaborative design workflows and enhanced functionality.

- CAD Software:SolidWorks can exchange design data with other CAD software, such as AutoCAD or Revit, allowing for interoperability and collaboration between different design teams.

- Simulation Software:SolidWorks can integrate with simulation software like ANSYS or Abaqus, enabling advanced analysis and optimization of designs.

- CAM Software:SolidWorks can interface with CAM software like Mastercam or Fusion 360, facilitating manufacturing process planning and CNC machine programming.

- Project Management Software:SolidWorks can be integrated with project management software like Jira or Asana, enabling collaborative design workflows, task management, and progress tracking.

Benefits of Multi-Disciplinary Design

SolidWorks facilitates multi-disciplinary design projects, offering numerous benefits:

- Improved Communication and Collaboration:SolidWorks enables seamless communication and collaboration among different design teams, ensuring a shared understanding of design requirements and progress.

- Reduced Design Errors and Rework:SolidWorks allows for early detection of conflicts and design errors, minimizing rework and ensuring efficient design processes.

- Enhanced Design Efficiency and Faster Time to Market:SolidWorks streamlines design workflows, enabling faster iteration and optimization of designs, resulting in quicker time to market.

- Increased Design Quality and Product Performance:SolidWorks enables comprehensive analysis and optimization of designs, leading to improved product quality, performance, and reliability.

SolidWorks for Specific Industries

SolidWorks is a powerful 3D CAD software used across various industries, each with unique design requirements, manufacturing processes, and challenges. Let’s explore how SolidWorks is used in three prominent industries: automotive, aerospace, and consumer goods.

Automotive

SolidWorks is widely used in the automotive industry for designing and manufacturing vehicles, engines, and various components. The software’s capabilities in creating detailed 3D models, analyzing performance, and optimizing designs for safety, efficiency, and cost make it an indispensable tool.Here are some specific applications of SolidWorks in the automotive industry:

- Vehicle Design:SolidWorks is used to create 3D models of complete vehicles, including exterior and interior designs, chassis, and bodywork. The software’s advanced surfacing tools and assembly capabilities enable designers to create complex shapes and intricate details.

- Engine Design:SolidWorks is used to design and analyze engine components, such as pistons, connecting rods, and cylinder heads. The software’s FEA (Finite Element Analysis) capabilities allow engineers to simulate the performance of engine components under various loads and conditions.

- Manufacturing Processes:SolidWorks plays a crucial role in the manufacturing process, facilitating the creation of detailed drawings, production plans, and tooling designs. The software’s CAM (Computer-Aided Manufacturing) features allow engineers to generate CNC (Computer Numerical Control) programs for machining and other manufacturing processes.

SolidWorks users in the automotive industry face unique challenges, including:

- Complex Simulations:Automotive designs require complex simulations to analyze factors like crashworthiness, aerodynamics, and fuel efficiency. SolidWorks addresses this challenge with advanced simulation tools like FEA, CFD (Computational Fluid Dynamics), and multibody dynamics.

- Data Management:Automotive projects involve managing vast amounts of data, including design files, simulation results, and manufacturing information. SolidWorks helps manage this data with its PDM (Product Data Management) system, which provides centralized storage, version control, and collaboration features.

- Collaboration:Automotive development often involves collaboration between multiple departments, such as design, engineering, and manufacturing. SolidWorks supports this collaboration with its data sharing and communication tools.

Aerospace

SolidWorks is a critical tool in the aerospace industry, where designs must meet stringent safety standards and perform reliably in extreme conditions. SolidWorks’ ability to handle lightweight materials, complex geometries, and tight tolerances makes it an ideal choice for aerospace applications.Here’s how SolidWorks is used in the aerospace industry:

- Aircraft Design:SolidWorks is used to design and manufacture aircraft components, including fuselages, wings, and control surfaces. The software’s advanced surfacing and assembly capabilities enable the creation of complex shapes and intricate details.

- Spacecraft and Satellite Design:SolidWorks is used to design spacecraft and satellites, including their structural components, propulsion systems, and payload modules. The software’s ability to handle complex geometries and lightweight materials is essential for these applications.

- Stress Analysis:Aerospace designs require rigorous stress analysis to ensure structural integrity. SolidWorks’ FEA capabilities allow engineers to simulate the performance of components under various loads and conditions, ensuring they meet safety standards.

SolidWorks users in the aerospace industry face specific challenges:

- Lightweight Materials:Aerospace designs often require the use of lightweight materials, such as composites and aluminum alloys. SolidWorks provides tools for working with these materials, including material properties databases and simulation capabilities.

- Complex Geometries:Aerospace designs often involve complex geometries, such as curved surfaces and intricate details. SolidWorks’ advanced surfacing and assembly tools allow engineers to create and manage these geometries.

- Tight Tolerances:Aerospace components must meet tight tolerances to ensure proper assembly and performance. SolidWorks provides tools for managing tolerances and ensuring that designs meet specifications.

Consumer Goods

SolidWorks is widely used in the consumer goods industry, where designs must be both functional and aesthetically pleasing. SolidWorks’ capabilities in surface modeling, rendering, and product lifecycle management make it an ideal choice for consumer goods applications.Here’s how SolidWorks is used in the consumer goods industry:

- Electronics Design:SolidWorks is used to design and manufacture electronics, such as smartphones, laptops, and tablets. The software’s advanced surfacing and assembly capabilities enable the creation of sleek and ergonomic designs.

- Appliance Design:SolidWorks is used to design and manufacture appliances, such as refrigerators, washing machines, and ovens. The software’s ability to handle complex geometries and assemblies is essential for these applications.

- Furniture Design:SolidWorks is used to design and manufacture furniture, such as chairs, tables, and beds. The software’s rendering capabilities allow designers to create realistic visualizations of their designs.

SolidWorks users in the consumer goods industry face specific challenges:

- Rapid Prototyping:Consumer goods companies need to rapidly prototype and test new designs to meet consumer demands. SolidWorks’ 3D printing capabilities and its integration with other prototyping tools allow for rapid prototyping.

- Cost-Effective Manufacturing:Consumer goods companies must find ways to manufacture products cost-effectively. SolidWorks’ CAM features allow engineers to optimize manufacturing processes and reduce production costs.

- Meeting Consumer Demands:Consumer goods companies must meet consumer demands for innovation and functionality. SolidWorks’ design tools and its integration with other product lifecycle management systems help companies meet these demands.

SolidWorks Community and Resources

Joining the SolidWorks community is like joining a club of passionate engineers and designers. It’s a fantastic way to level up your SolidWorks skills, get help when you’re stuck, and even connect with potential employers. Think of it as a network of support and shared knowledge that can help you achieve your SolidWorks goals.

Benefits of Joining the SolidWorks Community

Connecting with the SolidWorks community brings numerous advantages, including:

- Learning from Experts:The community is filled with seasoned SolidWorks users who are eager to share their knowledge and expertise. You can learn new techniques, discover hidden features, and get insights into best practices from experienced professionals. Imagine having a vast library of SolidWorks knowledge at your fingertips!

- Solving Problems Quickly:When you hit a roadblock in SolidWorks, the community is your ultimate problem-solving resource. You can post your questions in forums, get quick feedback, and find solutions from others who have encountered similar challenges.

- Professional Development:Engaging with the SolidWorks community can boost your professional growth. You can participate in discussions, contribute to projects, and even network with potential employers. It’s a great way to build your reputation and connect with like-minded individuals.

Popular Online Resources for SolidWorks Users

Here are some of the most popular online resources for SolidWorks users:

| Resource Name | Description | Primary Focus |

|---|---|---|

| SolidWorks Forums | A bustling online forum where users can ask questions, share tips, and discuss various SolidWorks topics. | Forums |

| SolidWorks User Groups | Local and online groups where SolidWorks enthusiasts can meet, share projects, and learn from each other. | User Groups |

| SolidWorks YouTube Channel | Official channel with tutorials, demos, and other helpful content for learning SolidWorks. | Tutorials and Videos |

| SolidWorks Blog | A blog featuring articles, news, and updates about SolidWorks and related technologies. | News and Updates |

| SolidWorks Facebook Group | A social media platform for connecting with other SolidWorks users and sharing ideas. | Social Media |

Tips for Effective Participation in SolidWorks Forums

To make the most of your participation in SolidWorks forums, remember these tips:

- Ask Clear Questions:Be specific about your problem or question. Provide details about your SolidWorks version, the steps you’ve taken, and any error messages you’ve encountered. The more information you provide, the better the chances of getting a helpful response.

- Provide Context:Explain the context of your question. What are you trying to achieve? What are your design goals? Providing context helps others understand your situation and offer relevant solutions.

- Engage Respectfully:Treat other forum members with respect. Be polite and avoid inflammatory language. Remember that everyone is there to learn and help each other.

SolidWorks User Groups: A Platform for Professional Development

SolidWorks user groups can significantly contribute to your professional development in various ways:

- Networking Opportunities:User groups offer a fantastic opportunity to connect with other SolidWorks users, share experiences, and build professional relationships. You can learn from their expertise, collaborate on projects, and even explore job opportunities.

- Skill Enhancement:Many user groups host workshops, presentations, and training sessions on various SolidWorks topics. These events can help you enhance your skills, learn new techniques, and stay up-to-date with the latest developments in SolidWorks.

- Community Involvement:Participating in user groups can give you a sense of belonging and community. You can contribute to discussions, share your expertise, and help others learn. It’s a rewarding way to give back to the SolidWorks community.

Query Resolution

Is SolidWorks free to use?

No, SolidWorks is a paid software with different licensing options. However, they offer a free trial version for users to explore its features.

What are the system requirements for running SolidWorks?

SolidWorks has specific system requirements that depend on the version you’re using. You can find detailed information on their website.

What are the best ways to practice SolidWorks?

Practice is key! Start with simple projects, gradually increasing complexity. Online tutorials and practice files can be great resources.

Are there any SolidWorks certifications available?

Yes, there are various SolidWorks certifications that can demonstrate your proficiency and enhance your career prospects.

What are the career opportunities for SolidWorks users?

SolidWorks skills are highly sought after in various industries, including manufacturing, engineering, design, and more.