How long does it take to learn SolidWorks? This question is on the minds of many aspiring engineers, designers, and anyone looking to harness the power of this 3D CAD software. The journey to mastering SolidWorks is a rewarding one, but it requires dedication, practice, and a clear understanding of the fundamental concepts.

The time it takes to learn SolidWorks depends on several factors, including your prior CAD experience, your learning style, and the amount of time you’re willing to dedicate to practice. For beginners with no prior CAD experience, it’s reasonable to expect a learning curve that involves mastering the basics, exploring essential features, and building confidence through hands-on projects.

As you progress, you’ll delve deeper into advanced techniques, such as surfacing, simulation, and customization, expanding your skillset and allowing you to tackle more complex designs.

Factors Influencing Learning Time

The time it takes to learn SolidWorks can vary significantly based on several factors, including prior experience, learning style, and dedication.

Prior CAD Experience

Having prior experience with other CAD software can significantly accelerate the learning process. If you’re familiar with the basic concepts of 3D modeling, such as sketching, extrusion, and assembly, you’ll grasp the fundamentals of SolidWorks more quickly. Familiarity with similar CAD software like AutoCAD or Inventor can help you adapt to SolidWorks’ interface and workflow more easily.

Learning Style and Aptitude

Everyone learns differently. Some people are visual learners and benefit from watching tutorials or working through hands-on projects. Others prefer a more structured approach, learning through step-by-step instructions and exercises. Your natural aptitude for spatial reasoning and problem-solving also plays a role.

If you have a strong spatial sense and enjoy working with technical concepts, you may find SolidWorks easier to learn.

Dedicated Practice Time and Consistent Effort

Mastering SolidWorks requires consistent practice and dedicated effort. The more time you spend working with the software, the more comfortable you’ll become with its features and functionalities. It’s important to set aside dedicated time for learning and practicing, even if it’s just for a few hours each week.

Learning Resources and Approaches

Navigating the world of SolidWorks can be exciting, but it also requires a structured approach. This section will guide you through the available resources and explore different learning strategies to help you master this powerful software.

Recommended Learning Resources

Choosing the right learning resources is crucial for a successful SolidWorks journey. Here’s a curated list to help you get started:

- Online Courses:Platforms like Udemy, Coursera, and Skillshare offer comprehensive SolidWorks courses, covering everything from basic concepts to advanced modeling techniques. These courses provide structured learning paths, interactive exercises, and often include project-based assignments.

- SolidWorks Tutorials:YouTube is a treasure trove of free SolidWorks tutorials. Channels like “SolidWorks Tutorials,” “CAD CAM Tutorials,” and “Engineering.com” offer a wide range of tutorials covering specific features, techniques, and real-world applications.

- Official SolidWorks Documentation:SolidWorks provides extensive documentation on its website, including user guides, tutorials, and technical articles. This resource is invaluable for in-depth information and specific feature explanations.

- SolidWorks Books:Several books are available that delve into SolidWorks fundamentals and advanced concepts. Popular options include “SolidWorks for Dummies,” “Mastering SolidWorks,” and “SolidWorks: A Comprehensive Guide.”

Learning Approaches

Different learning styles suit different individuals. Here’s a comparison of common learning approaches:

- Self-Paced Study:This approach offers flexibility and allows you to learn at your own pace. You can choose resources that resonate with your learning style and focus on areas that interest you most. However, self-paced study requires discipline and self-motivation to stay on track.

- Classroom Training:Formal classroom training provides a structured learning environment with expert guidance. You can ask questions directly, receive personalized feedback, and interact with fellow learners. However, classroom training is often more expensive and requires commitment to a specific schedule.

- Mentorship:Having a mentor who can provide personalized guidance and support can be invaluable. Mentors can offer real-world insights, troubleshoot challenges, and help you develop your skills. Finding a mentor can be challenging, but networking within your field or online communities can help.

Comprehensive Learning Plan

Combining various resources and approaches can create a comprehensive learning plan that caters to your needs and learning style. Here’s a suggested plan:

- Start with the Basics:Begin with a foundational online course or a beginner’s book to understand the core concepts of SolidWorks, including user interface, modeling tools, and basic design principles.

- Practice Regularly:Consistent practice is key to mastering SolidWorks. Set aside dedicated time for practicing tutorials, working on personal projects, or following along with online courses.

- Explore Advanced Features:Once you’ve gained a solid foundation, delve into more advanced features, such as assemblies, drawings, simulations, and data management. Focus on areas relevant to your specific needs and interests.

- Seek Feedback:Share your work with peers, mentors, or online communities to receive constructive feedback and learn from others’ experiences.

- Stay Updated:SolidWorks is constantly evolving with new features and updates. Keep up-to-date with the latest releases and advancements through online resources, webinars, or industry events.

3. Essential SolidWorks Concepts

SolidWorks, a powerful 3D CAD software, offers a comprehensive set of tools and functionalities for designing, analyzing, and manufacturing products. Mastering the essential SolidWorks concepts is crucial for efficiently utilizing its capabilities. This section delves into key areas that form the foundation of SolidWorks proficiency.

Sketching Fundamentals

Sketching is the cornerstone of SolidWorks modeling. It involves creating 2D shapes that serve as the basis for 3D features. A well-defined sketch ensures accurate and stable 3D models.

- Importance of Sketching:Sketches provide the foundation for all 3D features in SolidWorks. They define the shape, size, and geometry of the features that will be created. A well-defined sketch is crucial for creating accurate and stable 3D models.

- Sketching Constraints:Constraints are essential for defining the geometry and relationships between sketch entities. They ensure that sketches are fully defined and that the resulting 3D models are accurate and predictable.

- Horizontal and Vertical Constraints:These constraints define the orientation of sketch entities relative to the horizontal and vertical axes.

They ensure that lines, arcs, and other entities are aligned correctly.

- Parallel and Perpendicular Constraints:These constraints define the relationship between two or more sketch entities. Parallel constraints ensure that lines or arcs are parallel to each other, while perpendicular constraints ensure that they are perpendicular to each other.

- Tangent Constraints:Tangent constraints ensure that two entities are tangent to each other, meaning they share a common point and a common tangent line. This is useful for creating smooth transitions between curves and lines.

- Coincident Constraints:Coincident constraints ensure that two entities share the same endpoint or midpoint. This is useful for aligning and connecting different parts of a sketch.

- Equal Constraints:Equal constraints ensure that two or more entities have the same length or radius. This is useful for creating symmetrical shapes and for ensuring consistency in the dimensions of a sketch.

- Horizontal and Vertical Constraints:These constraints define the orientation of sketch entities relative to the horizontal and vertical axes.

- Creating Basic Geometric Shapes:SolidWorks provides a wide range of tools for creating basic geometric shapes, including lines, circles, arcs, rectangles, and polygons.

- Lines:Lines are the most basic sketch entity and are used to create straight edges.

- Circles:Circles are used to create circular shapes.

- Arcs:Arcs are used to create curved sections of a circle.

- Rectangles:Rectangles are used to create rectangular shapes.

- Polygons:Polygons are used to create shapes with multiple sides.

- Fully Defined Sketches:A fully defined sketch is one where all the geometric relationships between entities are established through constraints. This ensures that the sketch is rigid and does not have any degrees of freedom. A fully defined sketch is essential for creating stable and accurate 3D models.

- Common Sketching Techniques:SolidWorks offers several techniques for creating sketches efficiently.

- Using the Smart Dimension Tool:The Smart Dimension tool automatically creates dimensions that are relevant to the selected sketch entities.

- Using the Construction Line Tool:Construction lines are temporary lines that are not part of the final sketch. They are useful for guiding the creation of other sketch entities.

- Using the Trim and Extend Tools:The Trim and Extend tools are used to modify sketch entities by removing or extending their segments.

- Using the Offset Tool:The Offset tool creates a copy of a sketch entity at a specified distance.

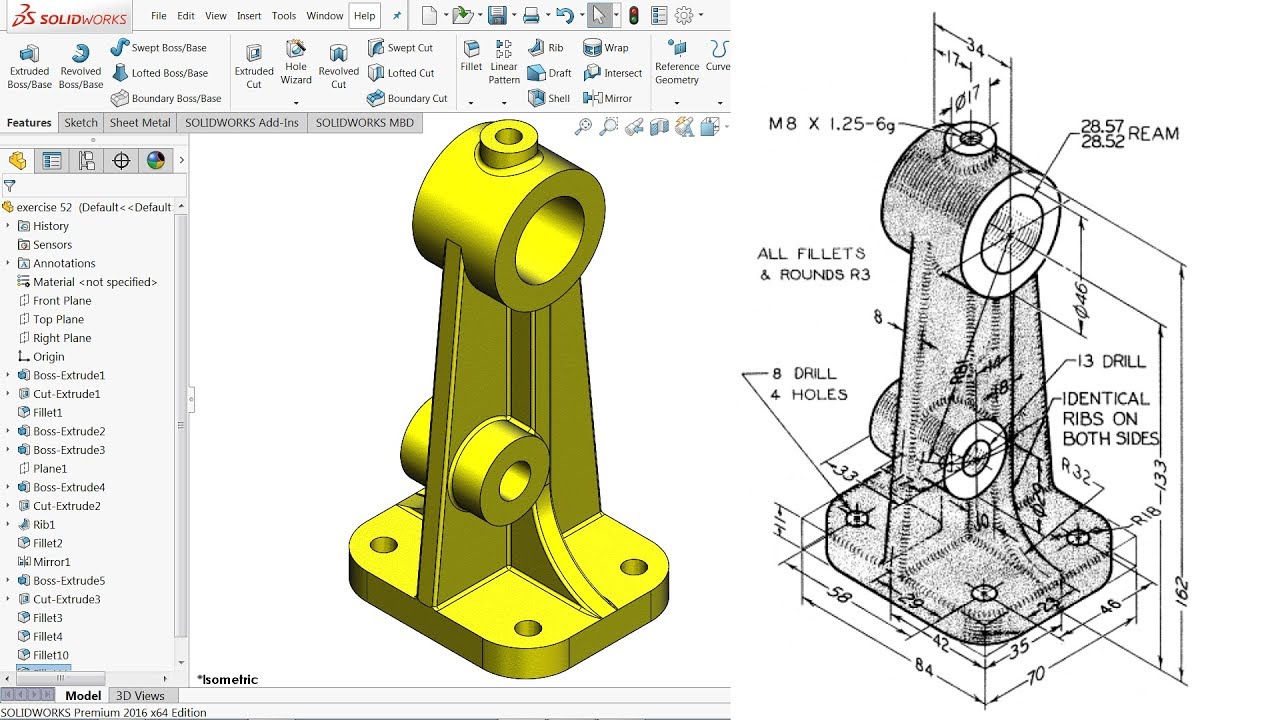

Feature Creation

Features are the building blocks of 3D models in SolidWorks. They represent the different geometric shapes and operations that are applied to a sketch to create a 3D object.

- Concept of Features:Features are the fundamental building blocks of 3D models in SolidWorks. They represent the various geometric shapes and operations that are applied to a sketch to create a 3D object.

- Types of Features:SolidWorks offers a wide variety of features to create complex 3D models.

- Extrude:The Extrude feature creates a 3D solid by extending a sketch along a specified direction.

- Revolve:The Revolve feature creates a 3D solid by rotating a sketch around a specified axis.

- Sweep:The Sweep feature creates a 3D solid by sweeping a sketch along a specified path.

- Loft:The Loft feature creates a 3D solid by connecting two or more profiles along a specified path.

- Shell:The Shell feature creates a hollow 3D solid by removing material from a solid object.

- Cut:The Cut feature creates a void in a solid object by subtracting material.

- Fillet:The Fillet feature rounds the edges of a solid object.

- Chamfer:The Chamfer feature creates a beveled edge on a solid object.

- Creating Basic Features:SolidWorks provides a user-friendly interface for creating features. The Feature Manager design tree provides a hierarchical view of all features in a model.

- Feature History:SolidWorks maintains a history of all features that have been created in a model. This feature history allows users to easily modify and edit existing features.

- Combining Features:Multiple features can be combined to create complex geometries. The order in which features are created can significantly affect the final shape of the model.

Assemblies

Assemblies in SolidWorks are used to combine multiple components into a single functional unit. They allow designers to create realistic models of products and systems.

- Purpose of Assemblies:Assemblies in SolidWorks are used to combine multiple components into a single functional unit. They allow designers to create realistic models of products and systems, enabling them to analyze their performance and identify potential design issues before manufacturing.

- Assembly Constraints:Assembly constraints are used to define the relationships between components in an assembly. These constraints ensure that the components are assembled correctly and that their relative positions are maintained.

- Mate:Mate constraints define a fixed relationship between two components. They ensure that the components are aligned and that their relative positions are maintained.

- Flush:Flush constraints ensure that two faces of components are aligned and that they are at the same level.

- Tangent:Tangent constraints ensure that two faces of components are tangent to each other.

- Distance:Distance constraints define a fixed distance between two components.

- Angle:Angle constraints define a fixed angle between two components.

- Assembling Components:Components are assembled by placing them in the assembly environment and applying constraints to define their relationships.

- Assembly Mates:Assembly mates are used to define the relationships between components in an assembly. They allow for flexible assembly configurations and provide a way to simulate the movement of components.

- Common Assembly Techniques:SolidWorks offers various techniques for creating assemblies efficiently.

- Using the Mate Tool:The Mate tool is used to define a fixed relationship between two components.

- Using the Assembly Constraints:Assembly constraints are used to define the relationships between components in an assembly.

- Using the Assembly Features:Assembly features are used to create and manage assembly relationships.

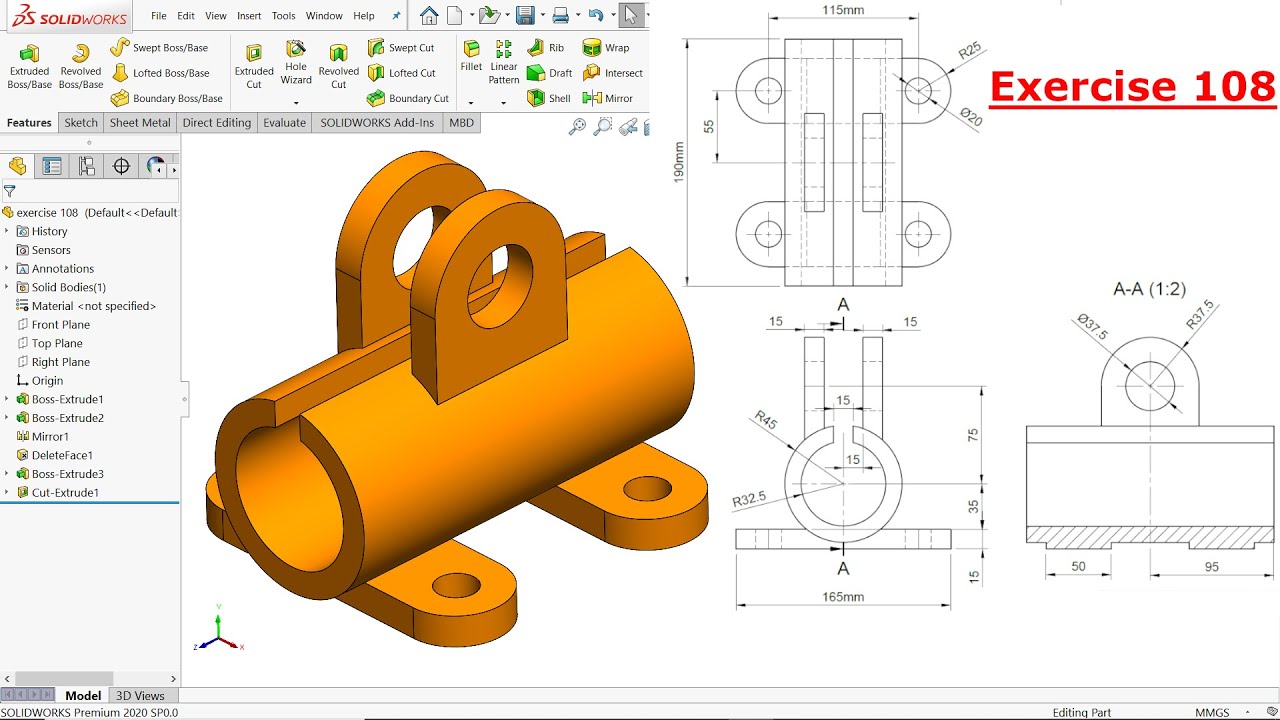

Drawings

Drawings are 2D representations of 3D models that communicate design intent and specifications. They are essential for manufacturing, documentation, and communication.

- Role of Drawings:Drawings are 2D representations of 3D models that serve as the primary means of communication and documentation for engineering designs. They provide a clear and concise visual representation of the product’s geometry, dimensions, and other important details.

- Types of Drawing Views:SolidWorks allows users to create various types of drawing views to represent the 3D model from different perspectives.

- Front View:The front view shows the object as if you are looking at it from the front.

- Top View:The top view shows the object as if you are looking at it from the top.

- Side View:The side view shows the object as if you are looking at it from the side.

- Isometric View:The isometric view shows the object in a 3D perspective.

- Section View:The section view shows the internal structure of the object by cutting through it.

- Creating a Drawing:Drawings are created by projecting the 3D model onto a 2D plane. SolidWorks provides tools for creating various types of views, adding dimensions, and annotating the drawing.

- Annotations:Annotations are text and symbols that are added to drawings to provide additional information. They include dimensions, notes, and other details that are essential for manufacturing and understanding the design.

- Common Drawing Techniques:SolidWorks offers various techniques for creating drawings efficiently.

- Using the Drawing View Tool:The Drawing View tool is used to create various types of drawing views from the 3D model.

- Using the Dimension Tool:The Dimension tool is used to add dimensions to the drawing.

- Using the Note Tool:The Note tool is used to add notes and other text annotations to the drawing.

Essential Tools and Functionalities

SolidWorks offers a wide range of tools and functionalities that cater to various design needs. These tools are categorized based on their purpose and application.

| Tool/Functionality | Description | Application |

|---|---|---|

| Sketch Tools | Tools for creating and modifying sketches (lines, circles, arcs, etc.) | Creating 2D shapes as the basis for 3D features |

| Feature Tools | Tools for creating and modifying 3D features (extrude, revolve, sweep, etc.) | Building complex 3D models |

| Assembly Tools | Tools for assembling and constraining multiple components | Creating functional assemblies |

| Drawing Tools | Tools for creating and annotating 2D drawings | Communicating design intent and specifications |

| Simulation Tools | Tools for performing structural analysis and motion studies | Evaluating the performance of designs |

| Customization Tools | Tools for customizing the SolidWorks interface and workflows | Tailoring SolidWorks to specific needs |

Navigating the SolidWorks Interface

The SolidWorks interface is designed to provide users with a streamlined and intuitive experience. Understanding the layout and key components of the interface is crucial for efficient navigation.

- Interface Layout:The SolidWorks interface consists of several key components.

- Command Manager:The Command Manager provides access to the various tools and commands in SolidWorks.

- Feature Manager Design Tree:The Feature Manager Design Tree provides a hierarchical view of all features in a model.

- Graphics Area:The Graphics Area is where the 3D model is displayed.

- Navigation Tools:SolidWorks provides various navigation tools for exploring 3D models.

- Pan:The Pan tool is used to move the view of the model around the screen.

- Zoom:The Zoom tool is used to magnify or reduce the view of the model.

- Rotate:The Rotate tool is used to rotate the view of the model.

- Manager and Feature Manager:The Manager and Feature Manager provide access to various tools and functionalities, including the ability to manage features, create new components, and perform other tasks.

- Completing Basic Tasks:The SolidWorks interface is designed to make it easy to complete basic tasks, such as creating sketches, extruding features, and assembling components.

4. Practical Applications and Projects

Designing complex assemblies is a crucial skill in SolidWorks, allowing you to create intricate systems with multiple moving parts. This section delves into the practical applications of SolidWorks by providing step-by-step guides and real-world examples to help you master the process of designing complex assemblies.

4.1. Beginner SolidWorks Projects

These beginner projects introduce fundamental SolidWorks concepts and techniques for designing simple objects and assembling basic components.

- Project 1: Simple Object Design: This project involves creating a basic object like a pencil holder or a simple box using SolidWorks. You’ll learn fundamental skills like sketching, extrusion, and basic features. The project will also guide you through creating dimensions, applying materials, and generating drawings.

- Project 2: Assembly of Basic Components: This project involves creating multiple simple parts, such as a screw, nut, and washer. You’ll then assemble these parts into a simple mechanism, like a bolt and nut assembly. The project will explain the process of creating mates and constraints for proper assembly.

4.2. Intermediate SolidWorks Projects

These intermediate projects build upon the foundation laid in the beginner projects, introducing more complex design concepts and features.

- Project 3: Designing a Functional Mechanism: This project involves designing a more complex mechanism, such as a gear train or a simple lever system. You’ll explore advanced features like sweeps, lofts, and patterns for creating complex shapes. The project will also include instructions on analyzing the mechanism’s motion and stress using SolidWorks simulation tools.

- Project 4: Product Design and Manufacturing: This project involves designing a product like a small tool or a household item. You’ll consider design for manufacturing principles, such as ease of assembly and production cost. The project will guide you through creating detailed manufacturing drawings, including dimensions, tolerances, and material specifications.

4.3. Advanced SolidWorks Projects

These advanced projects challenge you to design complex assemblies with multiple moving parts, incorporating industry standards and best practices.

- Project 5: Designing a Complex Assembly: This project involves designing a complex assembly with multiple moving parts, such as a small engine or a robotic arm. You’ll utilize advanced features like assemblies, sub-assemblies, and motion studies. The project will also guide you through implementing design reviews and incorporating feedback for optimization.

- Project 6: Real-World Design Challenge: This project involves choosing a real-world design challenge, such as designing a sustainable product or improving an existing design. You’ll conduct thorough research and analysis to identify design requirements and constraints. The project will guide you through utilizing SolidWorks to develop a solution and create a detailed presentation with justification.

4.4. Industry Standards and Best Practices

These projects emphasize the importance of adhering to industry standards and best practices for creating professional and effective SolidWorks designs.

- Project 7: Applying Industry Standards: This project involves researching and understanding relevant industry standards for your chosen field, such as ASME Y14.5 for mechanical drawings. You’ll incorporate these standards into SolidWorks projects, including dimensioning, tolerances, and annotations. The project will explain the importance of adhering to industry standards for communication and quality control.

- Project 8: Implementing Best Practices: This project involves exploring best practices for SolidWorks modeling, such as using proper naming conventions, organizing files, and creating documentation. You’ll demonstrate the benefits of following best practices for efficiency, collaboration, and project management.

Designing a Complex Assembly in SolidWorks

Designing a complex assembly in SolidWorks involves a systematic approach that ensures accurate component placement, proper constraints, and effective management of multiple parts. Here’s a step-by-step guide:

- Part Design:Begin by designing each individual component of the assembly in SolidWorks. This involves creating sketches, extruding features, and applying dimensions and materials. It’s essential to consider the function and interaction of each component within the assembly during this stage.

- Assembly Creation:Once all components are designed, create a new assembly file in SolidWorks. Import the individual parts into the assembly environment. The assembly environment allows you to arrange and constrain components to create a functional system.

- Component Placement:Place each component in its designated position within the assembly. Use the appropriate tools and techniques to achieve accurate placement, ensuring that all components are correctly aligned and oriented.

- Constraint Application:Apply constraints to define the relationship between components. Constraints ensure that components move and interact as intended. Common constraints include mates, distances, and angles. Consider the required movement and interaction of components when applying constraints.

- Assembly Management:As the assembly grows in complexity, it’s crucial to manage its components effectively. Use tools like component groups and assembly features to organize and control the assembly structure. This helps to simplify the assembly process and improve its overall efficiency.

- Design Review:Conduct design reviews to evaluate the assembly’s functionality and identify potential issues. Utilize SolidWorks’ built-in analysis tools, such as motion studies and interference checks, to assess the assembly’s performance and identify areas for improvement.

- Industry Standards and Best Practices:Adhering to industry standards and best practices is essential for ensuring communication, quality control, and collaboration within a design team. This includes using standard dimensioning techniques, applying tolerances, and creating clear and concise documentation.

“A well-designed complex assembly should be easy to assemble, maintain, and disassemble. It should also meet all functional requirements and industry standards.”

5. Developing Proficiency and Expertise in SolidWorks

SolidWorks is a powerful 3D CAD software, but mastering it requires dedication and practice. As you progress beyond the fundamentals, you’ll encounter challenges and discover advanced features that enhance your design capabilities. This section explores strategies for overcoming hurdles, mastering key skills, and staying up-to-date with SolidWorks advancements.

5.1. Overcoming SolidWorks Hurdles

Beginning your SolidWorks journey can be exciting, but it’s also common to face obstacles along the way. These challenges are opportunities to learn and refine your approach. Understanding common hurdles and their solutions empowers you to tackle problems effectively and progress smoothly.

| Challenge | Troubleshooting Technique |

|---|---|

| Difficulty understanding complex commands or features | Explore the SolidWorks Help documentation or online tutorials specifically designed for beginners. These resources often break down complex concepts into simpler steps and provide visual aids. |

| Struggling to create precise geometry or complex shapes | Practice using the various sketching and modeling tools, focusing on developing your understanding of constraints and dimensions. Utilize the “Smart Dimension” tool to ensure accurate and consistent geometry. |

| Inability to troubleshoot errors or unexpected behavior | Review the SolidWorks error messages carefully. They often provide clues about the source of the problem. Utilize the “Error Log” feature to track and analyze past errors. |

| Lack of inspiration for design projects or ideas | Explore online design communities, participate in SolidWorks challenges, or browse design galleries for inspiration. These resources showcase diverse projects and techniques, sparking creativity and providing valuable learning opportunities. |

| Feeling overwhelmed by the vastness of SolidWorks features | Focus on learning a few key features at a time. Start with the core modeling tools and gradually expand your skillset as you gain confidence. Remember, SolidWorks is a journey, not a race. |

It’s crucial to remember that everyone learns at their own pace. Don’t get discouraged by challenges; embrace them as opportunities for growth.

5.2. Mastering SolidWorks Skills

As you progress, mastering specific SolidWorks features becomes crucial for creating efficient and sophisticated designs. Focus on developing proficiency in these essential areas:

- Advanced Surfacing:This feature allows you to create complex, organic shapes that are not easily achieved with traditional modeling techniques.

- Assembly Design:Mastering assembly design enables you to create complex products by combining multiple parts and managing their relationships.

- Simulation:Simulation tools allow you to test and analyze the behavior of your designs under various conditions, ensuring their functionality and performance.

To enhance your proficiency in these areas, consider these practice exercises:

- Advanced Surfacing:Design a complex organic shape, such as a car body or a piece of furniture, using the advanced surfacing tools.

- Assembly Design:Create a complex assembly, such as a bicycle or a mechanical device, ensuring proper fit and function between the parts.

- Simulation:Perform a stress analysis on a simple design, such as a beam or a bracket, to understand how it responds to external forces.

5.3. Keeping Up with SolidWorks Advancements

SolidWorks is constantly evolving, with new features and updates released regularly. Staying informed about these advancements is crucial for maximizing your productivity and leveraging the latest design capabilities.

- SolidWorks Community Forum:This forum provides a platform for users to connect, share knowledge, and discuss the latest updates and features. It’s an excellent resource for finding solutions to problems, learning from others, and staying informed about new releases.

- SolidWorks Blog:The official SolidWorks blog features articles, tutorials, and announcements about new features, updates, and industry trends. It’s a great source for staying up-to-date on the latest developments.

- SolidWorks User Groups:Local user groups offer opportunities to connect with other SolidWorks users, share best practices, and learn about new features and advancements through workshops and presentations.

6. Time Commitment and Realistic Expectations

Learning SolidWorks is a journey that requires dedication and consistent effort. While the exact time it takes to become proficient varies, understanding the factors involved and setting realistic expectations can significantly impact your progress.

Estimated Time Commitment for Proficiency Levels

To give you a better idea of the time investment involved, here’s a breakdown of estimated time commitments for achieving different proficiency levels in SolidWorks:| Proficiency Level | Estimated Time Commitment ||—|—|| Basic | 10-20 hours || Intermediate | 50-100 hours || Advanced | 200+ hours |Keep in mind that these are just estimates.

Your individual learning journey may differ based on several factors, including:* Prior CAD experience:If you have prior experience with other CAD software, you may be able to learn SolidWorks faster.

Learning style

Some people learn best through hands-on practice, while others prefer more structured tutorials.

Available practice time

The amount of time you dedicate to learning SolidWorks will directly impact your progress.

Setting Achievable Goals and Tracking Progress

Setting achievable goals and tracking your progress is crucial for staying motivated and on track during your SolidWorks learning journey. Breaking down the learning process into smaller, manageable goals can make it feel less daunting. Here are some suggestions for tracking your progress:* Complete tutorials:Many online resources offer tutorials for different SolidWorks features and functionalities.

Completing these tutorials can help you develop a solid foundation.

Create projects

Applying your knowledge through real-world projects can help solidify your understanding and build your confidence.

Participate in online forums

Engaging with the SolidWorks community can provide valuable insights, answer your questions, and motivate you to keep learning.Tracking your progress can be a great motivator. Seeing how far you’ve come can boost your confidence and keep you enthusiastic about your learning journey.

Learning Solidworks is like learning any new skill – it takes time and dedication. You can expect to spend a few months mastering the basics, but to become truly proficient, you’ll need to put in consistent effort. It’s like deciding whether to should i learn to ski or snowboard – you’ll need to invest time and practice to become comfortable and confident.

So, how long it takes to learn Solidworks depends on your commitment and learning style, but remember, it’s a rewarding journey with valuable skills to gain.

Continuous Learning in SolidWorks

Learning SolidWorks is an ongoing process. New features, software updates, and industry best practices are constantly evolving. To stay ahead of the curve and maximize your skills, it’s essential to embrace continuous learning.Here are some resources for ongoing learning:* Online courses:Numerous online platforms offer courses on advanced SolidWorks topics, industry-specific applications, and new features.

Forums

Engaging with the SolidWorks community through online forums can provide access to a wealth of knowledge and expertise.

Industry publications

Staying up-to-date with industry publications and blogs can help you learn about new trends and best practices.Continuous learning is not just about staying updated; it’s also about developing your skills and pushing your boundaries. By continuously challenging yourself, you can unlock your full potential in SolidWorks and become a highly skilled and sought-after professional.

SolidWorks Certification

Earning a SolidWorks certification demonstrates your proficiency in using the software, boosting your credibility and increasing your job prospects. It’s a valuable asset for anyone working in engineering, design, or manufacturing.

SolidWorks Certification Levels and Requirements

SolidWorks offers a range of certifications to cater to different skill levels and career paths. These certifications are recognized globally, validating your expertise and setting you apart from the competition.

- CSWA (Certified SolidWorks Associate): This entry-level certification validates your basic understanding of SolidWorks fundamentals, including modeling, sketching, and assembly. You’ll need to pass a 60-minute exam covering essential SolidWorks features.

- CSWP (Certified SolidWorks Professional): This certification recognizes your advanced skills in SolidWorks, including more complex modeling, advanced assemblies, and drawing creation. The exam is 120 minutes long and covers a broader range of features and applications.

- CSWE (Certified SolidWorks Expert): This certification is the highest level of SolidWorks certification, signifying mastery of advanced concepts and best practices. You’ll need to pass a 180-minute exam that includes challenging scenarios and complex modeling tasks.

Preparing for SolidWorks Certification Exams

Preparing for SolidWorks certification exams requires a structured approach and dedicated practice. Here are some strategies to maximize your chances of success:

- Review SolidWorks Fundamentals: Start by refreshing your knowledge of core SolidWorks concepts, including sketching, modeling, assembly, and drawing creation. Refer to official SolidWorks documentation, tutorials, and practice exercises.

- Practice with Exam-Style Questions: SolidWorks offers practice exams that simulate the real exam environment. Utilize these practice exams to familiarize yourself with the exam format, question types, and time constraints.

- Join Study Groups or Online Forums: Connect with other SolidWorks learners and professionals to exchange knowledge, discuss challenges, and share tips. Online forums and study groups can provide valuable insights and support during your preparation.

- Seek Guidance from Experienced Professionals: Consider reaching out to certified SolidWorks professionals or trainers for guidance and feedback. They can offer valuable insights into the exam content and provide personalized advice based on your specific needs.

Beyond the Basics

Once you’ve mastered the fundamentals of SolidWorks, it’s time to dive deeper into the world of advanced techniques. These skills will enable you to create more complex and sophisticated designs, optimize your models for performance, and streamline your workflow. This section will guide you through some of the key advanced techniques that can elevate your SolidWorks expertise.

Surfacing Mastery

Surfacing is a powerful tool in SolidWorks that allows you to create complex, organic shapes and geometries. Unlike traditional solid modeling, which relies on simple geometric shapes, surfacing allows you to define complex curves and surfaces, enabling you to model objects with intricate details and realistic appearances.

- Surfacing Tools in SolidWorks:SolidWorks offers a wide range of surfacing tools, each designed for specific tasks. Some of the most commonly used tools include:

- Sweep:This tool allows you to create a surface by sweeping a profile along a path. It’s particularly useful for creating complex curves and surfaces that are difficult to model using traditional solid modeling techniques.

- Loft:This tool creates a surface by interpolating between two or more profiles. It’s ideal for creating complex shapes with smooth transitions between different sections.

- Ruled Surface:This tool creates a surface by connecting two or more curves with straight lines. It’s useful for creating surfaces with a flat or slightly curved appearance.

- Fill:This tool creates a surface by filling a boundary defined by curves or edges. It’s useful for creating surfaces with irregular shapes or complex contours.

- Applications of Surfacing:Surfacing techniques are widely used in various industries, including:

- Product Design:Surfacing allows designers to create products with sleek, organic shapes, enhancing their aesthetic appeal and functionality. For example, designing a new smartphone with a curved back or a stylish sports car with aerodynamic lines.

- Automotive Design:Surfacing is essential for creating realistic models of vehicles, capturing the intricate curves and surfaces of car bodies, interiors, and exterior components.

- Architectural Design:Architects use surfacing to model complex building facades, curved roofs, and intricate interior designs, enabling them to visualize and refine their architectural visions.

Simulation for Design Optimization

Simulation plays a crucial role in modern engineering design, allowing engineers to evaluate the performance of their designs before they are physically built. SolidWorks offers a comprehensive simulation suite that enables engineers to perform various analyses, such as stress analysis, thermal analysis, and motion analysis.

- Setting Up and Running a Simulation:Performing a simulation in SolidWorks involves several steps:

- Define Material Properties:Select the appropriate material for your model and define its properties, such as Young’s modulus, Poisson’s ratio, and density.

- Apply Loads:Apply forces, pressures, or other loads to your model, simulating the conditions it will experience in real-world use.

- Define Constraints:Specify how your model is supported and how it interacts with its environment. This ensures that the simulation accurately reflects the real-world conditions.

- Run the Simulation:Once the simulation is set up, SolidWorks performs the analysis and generates results, including stress distributions, displacements, and temperature variations.

- Interpret Results:Analyze the simulation results to identify potential design flaws, areas of high stress, or other issues that may affect the performance of your design.

- Types of Simulations in SolidWorks:SolidWorks offers various simulation types, each designed for specific analysis purposes:

- Stress Analysis:This type of simulation analyzes the distribution of stresses within a model under applied loads. It helps engineers identify potential areas of failure or fatigue.

- Thermal Analysis:This type of simulation analyzes the temperature distribution within a model, considering heat transfer through conduction, convection, and radiation. It helps engineers design products that operate efficiently under various thermal conditions.

- Motion Analysis:This type of simulation analyzes the motion of a model over time, considering forces, constraints, and contact interactions. It helps engineers design mechanisms and assemblies that function smoothly and efficiently.

- Real-World Applications of Simulation:Simulation has been widely used to improve product design and reduce development costs in various industries:

- Automotive Industry:Simulation is used to optimize the design of car bodies, engines, and suspension systems, improving their performance, fuel efficiency, and safety.

- Aerospace Industry:Simulation is used to design and analyze aircraft components, such as wings, engines, and landing gear, ensuring their structural integrity and aerodynamic performance.

- Medical Device Industry:Simulation is used to design and analyze medical devices, such as implants, prosthetics, and surgical instruments, ensuring their safety and effectiveness.

Customization and Automation

SolidWorks allows users to customize the software to suit their specific needs and preferences. This customization capability can significantly enhance productivity by automating repetitive tasks, streamlining workflows, and creating a more personalized user experience.

- Customization in SolidWorks:SolidWorks offers various customization options, including:

- Macros:Macros are sequences of commands that can be recorded and played back to automate repetitive tasks. They can be used to perform complex operations with just a few clicks, saving time and reducing errors.

- Custom Properties:Custom properties allow you to define and manage additional data associated with your models. This can be used to track specific information, such as manufacturing tolerances, material specifications, or cost estimates.

- Custom Toolbars and Menus:You can create custom toolbars and menus to organize your most frequently used commands and tools, making them easily accessible.

- Templates:SolidWorks allows you to create custom templates for your designs, predefining settings, configurations, and features. This helps ensure consistency and efficiency in your work.

- Benefits of Customization:Mastering customization techniques can provide significant benefits for professional designers and engineers:

- Increased Productivity:Automating repetitive tasks with macros and custom properties can significantly improve your efficiency and free up time for more creative work.

- Enhanced Design Consistency:Using templates and custom properties can help ensure consistency across your designs, reducing errors and improving quality.

- Personalized Workflow:Customizing your SolidWorks environment to suit your preferences can make the software more intuitive and efficient to use.

9. Industry Use Cases and Examples

SolidWorks, a powerful CAD software, finds extensive application across various industries, from automotive to aerospace and consumer products. It empowers engineers and designers to create complex designs, analyze their performance, and optimize manufacturing processes.

Automotive

SolidWorks plays a crucial role in the automotive industry, particularly in the design and development of electric vehicles (EVs). The software’s capabilities enable engineers to address the unique challenges associated with EV development, such as battery integration and weight optimization.

- EV Chassis Design:SolidWorks enables engineers to design and analyze the chassis of EVs, considering factors like battery placement, weight distribution, and structural integrity. For example, Tesla, a leading EV manufacturer, leverages SolidWorks to design its chassis, ensuring optimal performance and safety.

- Aerodynamics Simulation:SolidWorks’ CFD analysis capabilities are essential for optimizing the aerodynamics of high-performance sports cars. By simulating airflow around the vehicle, engineers can identify areas for improvement, reducing drag and enhancing fuel efficiency. For instance, Porsche, renowned for its sports cars, utilizes SolidWorks CFD analysis to optimize the aerodynamic design of its vehicles.

- Complex Component Design:SolidWorks’ parametric modeling and assembly management features enable the design and manufacturing of intricate automotive components, such as engine blocks and transmissions. The software allows engineers to create complex geometries, manage multiple parts in an assembly, and ensure precise fit and function.

For example, BMW, a leading automotive manufacturer, employs SolidWorks to design and manufacture its engine blocks and transmissions.

Aerospace

SolidWorks is indispensable in the aerospace industry, where engineers strive for lightweight designs, structural integrity, and precise tolerances.

- Aircraft Design:SolidWorks facilitates the design of aircraft wings and fuselages, considering structural analysis, weight reduction, and aerodynamic optimization. For instance, Boeing, a leading aircraft manufacturer, uses SolidWorks to design its aircraft wings, ensuring optimal lift and stability.

- Satellite Component Development:SolidWorks plays a vital role in developing satellite components, taking into account extreme environmental conditions and precise tolerances. The software’s ability to handle complex geometries and simulate various scenarios enables engineers to create reliable and functional satellite components. For example, SpaceX, a leading space exploration company, uses SolidWorks to design its satellite components, ensuring they can withstand the harsh conditions of space.

- Rocket Engine Design:SolidWorks is essential for designing and simulating rocket engines, considering thermal analysis, material selection, and performance optimization. The software’s capabilities allow engineers to create robust and efficient rocket engines that can withstand extreme temperatures and pressures. For instance, Blue Origin, a space exploration company, utilizes SolidWorks to design its rocket engines, ensuring optimal performance and safety.

Consumer Products, How long does it take to learn solidworks

SolidWorks finds widespread use in the consumer products industry, enabling the creation of ergonomic designs, user-friendly interfaces, and durable products.

- Consumer Electronics:SolidWorks facilitates the design and development of consumer electronics, ensuring ergonomic designs and intuitive user interfaces. For example, Apple, a leading consumer electronics company, uses SolidWorks to design its products, ensuring a seamless user experience.

- Toy Design:SolidWorks plays a crucial role in the design and manufacturing of toys, prioritizing safety and durability. The software’s capabilities allow engineers to create engaging and safe toys that meet industry standards. For example, LEGO, a leading toy manufacturer, utilizes SolidWorks to design its toys, ensuring they are safe and durable for children.

- Furniture Design:SolidWorks supports the design of furniture, leveraging rendering and visualization tools to create realistic product prototypes. The software’s capabilities allow designers to create visually appealing and functional furniture pieces. For example, IKEA, a leading furniture retailer, uses SolidWorks to design its furniture, ensuring it is both aesthetically pleasing and functional.

Community and Support Resources: How Long Does It Take To Learn Solidworks

SolidWorks, being a widely used CAD software, boasts a vibrant community of users, experts, and enthusiasts who are always ready to assist and share their knowledge. This network can be a valuable resource for learning, problem-solving, and staying up-to-date with the latest developments in SolidWorks.Engaging with the SolidWorks community can significantly enhance your learning journey.

Accessing these resources can be instrumental in accelerating your proficiency and overcoming challenges you might encounter.

Online Forums and Communities

Joining online forums and communities dedicated to SolidWorks can provide you with a platform to connect with other users, ask questions, share your experiences, and learn from their expertise. These platforms are a great place to find solutions to specific problems, seek advice on best practices, and discuss new features or updates.

- SolidWorks Forums:The official SolidWorks forums are a valuable resource hosted by Dassault Systèmes, the developers of SolidWorks. Here, you can find discussions on various topics, technical support, and updates from the SolidWorks team.

- Other Online Communities:Several other online communities cater to SolidWorks users, such as Reddit, LinkedIn groups, and specialized forums. These platforms offer diverse perspectives and discussions on a wide range of SolidWorks topics.

Technical Support and Documentation

Dassault Systèmes provides comprehensive technical support and documentation for SolidWorks users. Accessing these resources can be crucial for troubleshooting issues, understanding software features, and resolving technical challenges.

- SolidWorks Help Center:The SolidWorks Help Center offers detailed documentation, tutorials, and FAQs that cover various aspects of the software.

- SolidWorks Customer Support:Dassault Systèmes provides dedicated customer support channels for users who require assistance with specific issues. This support can be accessed through phone, email, or online chat.

- SolidWorks Knowledge Base:The SolidWorks Knowledge Base contains a vast repository of articles, solutions, and troubleshooting tips that can be accessed by users.

Integration with Other Software

SolidWorks, being a powerful CAD software, doesn’t exist in isolation. It seamlessly integrates with a wide range of other design, engineering, and manufacturing software, creating a robust ecosystem for product development. This integration fosters a collaborative workflow, allowing teams to share data, streamline processes, and optimize efficiency.

Data Exchange and Collaboration

The ability to exchange data with other software is a cornerstone of SolidWorks’ integration capabilities. This enables seamless communication and collaboration among various stakeholders involved in the product development process.

- Native File Formats:SolidWorks supports various native file formats, including those used by other CAD software like AutoCAD, Inventor, and CATIA. This allows for direct import and export of designs, ensuring data integrity and minimizing compatibility issues.

- Industry Standard Formats:SolidWorks can also handle industry standard formats like STEP, IGES, and DXF, facilitating data exchange with a broader range of software applications. This ensures interoperability across different platforms and promotes wider collaboration.

- Data Sharing and Collaboration Tools:SolidWorks integrates with various data management and collaboration platforms like PDM (Product Data Management) systems and cloud-based services. These tools enable secure storage, version control, and collaborative access to design data, streamlining workflows and enhancing team productivity.

Integration with Simulation and Analysis Software

SolidWorks seamlessly integrates with simulation and analysis software, allowing engineers to conduct virtual testing and optimize designs before physical prototyping. This integration streamlines the design process and reduces time-to-market.

- SolidWorks Simulation:SolidWorks Simulation is a built-in module that offers a comprehensive suite of tools for structural, thermal, and fluid flow analysis. This allows engineers to analyze the performance of designs under various conditions and identify potential issues early in the development cycle.

- Third-Party Simulation Software:SolidWorks can also exchange data with third-party simulation software like ANSYS, Abaqus, and Nastran. This allows engineers to leverage specialized simulation capabilities for complex analyses and optimize designs for specific applications.

Integration with Manufacturing Software

SolidWorks integrates with manufacturing software, enabling a smooth transition from design to production. This integration streamlines the manufacturing process, reduces errors, and optimizes production efficiency.

- CAM (Computer-Aided Manufacturing) Software:SolidWorks integrates with CAM software like Mastercam and Fusion 360, allowing for direct generation of toolpaths and manufacturing instructions from SolidWorks models. This eliminates the need for manual data entry and reduces the risk of errors.

- PLM (Product Lifecycle Management) Software:SolidWorks integrates with PLM software like Teamcenter and Enovia, enabling comprehensive management of product data throughout its lifecycle. This facilitates collaboration among design, engineering, and manufacturing teams, ensuring data consistency and efficient product development.

Examples of SolidWorks Integration

- Design Collaboration:A design team working on a new automotive component can use SolidWorks to create the initial design and then export the model in STEP format for review by a team of engineers using a different CAD software. This enables collaborative design and feedback among different stakeholders.

- Simulation and Analysis:An engineer designing a new bridge can use SolidWorks to create a detailed model and then import it into ANSYS for structural analysis. This allows for virtual testing of the bridge’s performance under various load conditions, ensuring its structural integrity.

- Manufacturing Integration:A manufacturer producing custom-made parts can use SolidWorks to design the parts and then export the data to Mastercam for CNC machining. This streamlines the manufacturing process and ensures accuracy in production.

Future Trends and Innovations in SolidWorks

SolidWorks, a leading CAD software, is continuously evolving to meet the demands of the ever-changing engineering and manufacturing landscape. The integration of advanced technologies like generative design, augmented reality, cloud-based collaboration, and artificial intelligence is transforming how engineers design, create, and interact with products.

These innovations are not only enhancing design efficiency and accuracy but also opening up new possibilities for collaboration, visualization, and optimization.

Generative Design

Generative design in SolidWorks is a powerful tool that empowers engineers to explore a wide range of design possibilities by defining design goals and constraints. The software uses algorithms to generate multiple design variations that meet the specified criteria, allowing engineers to quickly evaluate different options and select the best solution.

- Key Features and Algorithms: Generative design in SolidWorks leverages sophisticated algorithms that analyze design parameters, such as material properties, manufacturing constraints, and performance requirements. These algorithms generate a range of design options, considering factors like weight, strength, and cost. The software also provides visual feedback on the performance and feasibility of each design variation.

- Benefits and Limitations: Generative design offers several benefits, including:

- Enhanced Creativity: It allows engineers to explore unconventional designs and solutions that they might not have considered otherwise.

- Improved Efficiency: By automating the design exploration process, it reduces the time and effort required to develop optimal designs.

- Optimized Performance: Generative design helps create designs that are optimized for specific performance requirements, such as weight reduction, strength improvement, or cost minimization.

However, generative design also has some limitations:

- Complexity: The process can be complex and require specialized knowledge to define design goals and constraints effectively.

- Computational Resources: Generative design algorithms can be computationally intensive, requiring significant processing power.

- Limited Control: While generative design offers a wide range of options, engineers may have limited control over the specific design features generated.

- Real-World Applications: Generative design has been successfully implemented in various industries, including aerospace, automotive, and consumer goods. For example, Airbus used generative design to optimize the design of a new aircraft cabin partition, reducing weight by 45% while maintaining structural integrity.

- Impact on Traditional Design Workflows: Generative design is expected to significantly impact traditional design workflows by shifting the focus from manual design iteration to automated exploration and optimization. Engineers will increasingly rely on generative design tools to generate innovative solutions, while focusing on refining and validating the final design.

Augmented Reality (AR)

AR technology overlays digital information onto the real world, enhancing the user’s perception of their surroundings. In SolidWorks, AR can be used to create immersive experiences that enable engineers to visualize, interact with, and collaborate on designs in a more intuitive and engaging way.

- Integration with SolidWorks: AR can be integrated with SolidWorks through various methods, such as using AR headsets, smartphones, or tablets. Engineers can view 3D models of their designs overlaid on real-world environments, allowing them to assess scale, fit, and functionality in a realistic context.

- Use Cases:

- Product Assembly: AR can guide technicians through complex assembly processes by providing step-by-step instructions and visual cues overlaid on the actual parts.

- Design Review: Engineers can use AR to conduct design reviews in a virtual environment, allowing stakeholders to visualize and interact with the design in a shared space.

- Training: AR can be used to create interactive training simulations that provide realistic hands-on experience with SolidWorks models, improving user comprehension and skill development.

- Challenges and Opportunities: Implementing AR in SolidWorks workflows presents both challenges and opportunities.

- Hardware and Software Requirements: AR technology requires specialized hardware and software, which can be expensive and may not be readily available to all users.

- User Experience: Ensuring a smooth and intuitive user experience with AR is crucial for its widespread adoption.

- Data Security: AR applications may require access to sensitive design data, raising concerns about data security and privacy.

Despite these challenges, AR offers significant potential for enhancing collaboration, visualization, and training in SolidWorks environments.

Cloud-Based Collaboration

Cloud-based platforms are becoming increasingly popular for SolidWorks design and data management, offering advantages such as enhanced accessibility, collaboration, and scalability.

- Benefits:

- Accessibility: Cloud-based platforms enable users to access SolidWorks files and data from anywhere with an internet connection, improving flexibility and collaboration among geographically dispersed teams.

- Collaboration: Cloud platforms facilitate seamless collaboration by allowing multiple users to work on the same design simultaneously, enabling real-time feedback and communication.

- Scalability: Cloud solutions offer scalable storage and computing resources, allowing businesses to adapt their infrastructure to meet changing demands.

- Cost Savings: Cloud-based solutions can reduce the need for expensive hardware and software licenses, leading to potential cost savings.

- Challenges:

- Internet Connectivity: Reliable internet connectivity is essential for cloud-based platforms, which can be a challenge in areas with limited or unreliable internet access.

- Data Security: Ensuring data security and privacy is crucial when using cloud-based platforms, as sensitive design information is stored and accessed remotely.

- Integration: Integrating cloud-based platforms with existing SolidWorks workflows and systems can be challenging, requiring careful planning and implementation.

- Examples of Cloud-Based SolidWorks Solutions:

- 3DEXPERIENCE Platform: Dassault Systèmes’ 3DEXPERIENCE platform offers a comprehensive cloud-based solution for SolidWorks design, collaboration, and data management. It provides tools for product lifecycle management (PLM), data visualization, and collaborative design.

- SOLIDWORKS PDM Professional: SOLIDWORKS PDM Professional is a cloud-based product data management (PDM) solution that enables secure storage, version control, and collaboration on SolidWorks files.

Artificial Intelligence (AI)

AI is rapidly transforming various industries, and SolidWorks is no exception. AI algorithms can be used to automate design optimization, predict maintenance needs, and enhance design accuracy.

- Role of AI in SolidWorks:

- Automated Design Optimization: AI can analyze design parameters and performance data to identify potential improvements and suggest design modifications for enhanced efficiency and performance.

- Predictive Maintenance: AI can analyze sensor data from manufactured products to predict potential failures and recommend preventive maintenance actions, reducing downtime and improving product reliability.

- Design Accuracy: AI algorithms can be used to detect and correct errors in design models, ensuring accuracy and consistency in the design process.

- Benefits of AI in SolidWorks:

- Enhanced Efficiency: AI can automate repetitive tasks and optimize design processes, freeing up engineers to focus on more complex and creative aspects of design.

- Improved Accuracy: AI algorithms can help identify and correct errors in design models, reducing the risk of costly mistakes.

- Predictive Insights: AI can provide valuable insights into product performance and potential issues, enabling proactive decision-making and optimization.

- Ethical Considerations:

- Bias: AI algorithms can inherit biases from the data they are trained on, which could lead to unfair or discriminatory outcomes.

- Transparency: The decision-making processes of AI algorithms can be opaque, making it difficult to understand how they reach their conclusions.

- Job Displacement: The increasing automation enabled by AI raises concerns about potential job displacement in the engineering and design fields.

Future Trends

The field of computer-aided design is constantly evolving, with emerging trends that are shaping the future of SolidWorks and other CAD software.

- Cloud-Native Design: The shift towards cloud-native design platforms will continue, offering enhanced accessibility, collaboration, and scalability.

- Internet of Things (IoT) Integration: CAD software will increasingly integrate with IoT devices, allowing engineers to design products that connect and interact with the physical world in real-time.

- Digital Twins: The use of digital twins, virtual representations of physical assets, will become more prevalent, enabling engineers to simulate and optimize product performance in a virtual environment.

- Sustainable Design: The focus on sustainable design practices will continue to grow, with CAD software incorporating tools and features that promote eco-friendly design principles.

- Advanced Simulation and Analysis: CAD software will continue to advance in simulation and analysis capabilities, allowing engineers to predict product performance with greater accuracy and detail.

The Importance of Continuous Learning

Learning SolidWorks is an ongoing journey, not a destination. The CAD landscape is constantly evolving, with new features, functionalities, and industry trends emerging regularly. Staying ahead of the curve requires a commitment to continuous learning.

The Value of Lifelong Learning in CAD

Continuous learning in the CAD field is not just about keeping up with the latest updates but also about developing a deeper understanding of the software’s capabilities and how they can be applied to solve complex engineering challenges. Here are some key benefits:

- Enhanced Skillset:Continuous learning allows you to expand your knowledge base, mastering advanced techniques and exploring new applications within SolidWorks. This leads to a more comprehensive and versatile skillset.

- Increased Efficiency:By staying informed about the latest updates and best practices, you can streamline your workflow and optimize your design process. This translates to increased efficiency and productivity.

- Improved Problem-Solving Abilities:Continuous learning exposes you to diverse approaches and solutions, enhancing your ability to tackle complex engineering problems creatively and effectively.

- Career Advancement:Demonstrating a commitment to continuous learning is highly valued by employers. It signifies your dedication to professional growth and your ability to adapt to evolving industry demands.

Commonly Asked Questions

What are the essential SolidWorks tools for beginners?

The essential SolidWorks tools for beginners include sketching tools (lines, circles, arcs), feature tools (extrude, revolve, sweep), and assembly tools (mates, constraints). These tools form the foundation for creating 3D models and assemblies.

Is SolidWorks difficult to learn?

SolidWorks has a learning curve, but it’s not inherently difficult. The key is to start with the basics, practice regularly, and seek help when needed. There are plenty of resources available to guide you through the process.

What are the benefits of learning SolidWorks?

Learning SolidWorks opens doors to a wide range of opportunities in engineering, design, and manufacturing. It equips you with the skills to create 3D models, design products, and contribute to innovative projects.

Is SolidWorks free?

SolidWorks offers a free trial, but a paid subscription is required for continued use. There are also educational versions available for students and educators.