In the realm of creative metal products, innovation knows no bounds. From architectural marvels to exquisite home décor, metal transforms into a canvas for imagination, where form and function intertwine seamlessly.

From skyscrapers that pierce the heavens to intricate sculptures that captivate the senses, creative metal products leave an indelible mark on our world. Architects, designers, and artisans harness the malleability of metal to create masterpieces that redefine the boundaries of possibility.

Definition and Scope of Creative Metal Products

Creative metal products encompass a wide range of objects and structures that combine artistic expression with functional utility. These products are characterized by their unique designs, exceptional craftsmanship, and innovative use of metals.

Examples of creative metal products can be found across various industries, including architecture, interior design, and fashion. In architecture, creative metal products are used to create striking facades, intricate railings, and decorative sculptures. In interior design, metal is employed to craft stylish furniture, lighting fixtures, and wall art.

In fashion, metal is used to create jewelry, accessories, and clothing with bold and eye-catching designs.

Types of Metals Used

The types of metals used in creative metal products vary depending on the desired properties and aesthetic appeal. Some of the most commonly used metals include:

- Steel:Known for its strength, durability, and versatility.

- Stainless steel:Offers excellent corrosion resistance and a sleek, modern look.

- Aluminum:Lightweight, durable, and resistant to corrosion.

- Copper:Malleable, ductile, and has a distinctive reddish-brown hue.

- Brass:An alloy of copper and zinc, with a warm, golden color.

Provide examples of creative metal products across various industries and sectors

Creative metal products are found in a wide range of industries and sectors, from architecture and construction to home décor and fashion.

Here are some examples of creative metal products across various industries and sectors:

Architecture and Construction

- Metal sculptures: These can be used to add a unique and eye-catching element to any building or landscape.

- Architectural elements: Metal can be used to create a variety of architectural elements, such as railings, balconies, and staircases.

- Building materials: Metal can be used as a building material for a variety of purposes, such as roofing, siding, and framing.

Home Décor

- Furniture: Metal can be used to create a variety of furniture pieces, such as chairs, tables, and beds.

- Lighting: Metal can be used to create a variety of lighting fixtures, such as chandeliers, sconces, and lamps.

- Accessories: Metal can be used to create a variety of home décor accessories, such as vases, sculptures, and candle holders.

Fashion

- Jewelry: Metal is a popular material for jewelry, such as necklaces, bracelets, and earrings.

- Clothing: Metal can be used to create a variety of clothing items, such as dresses, tops, and skirts.

- Accessories: Metal can be used to create a variety of fashion accessories, such as belts, bags, and shoes.

Other Creative Metal Products

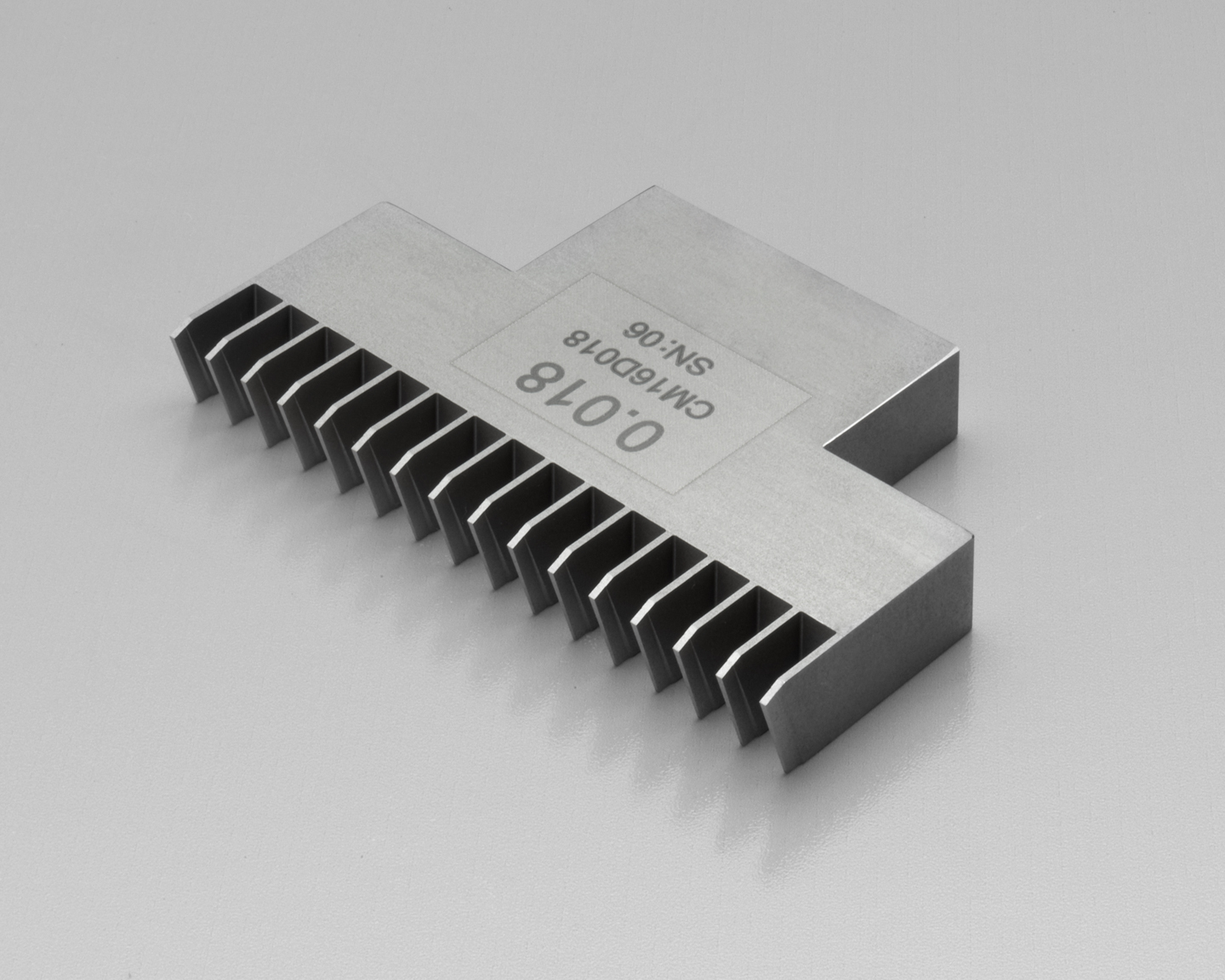

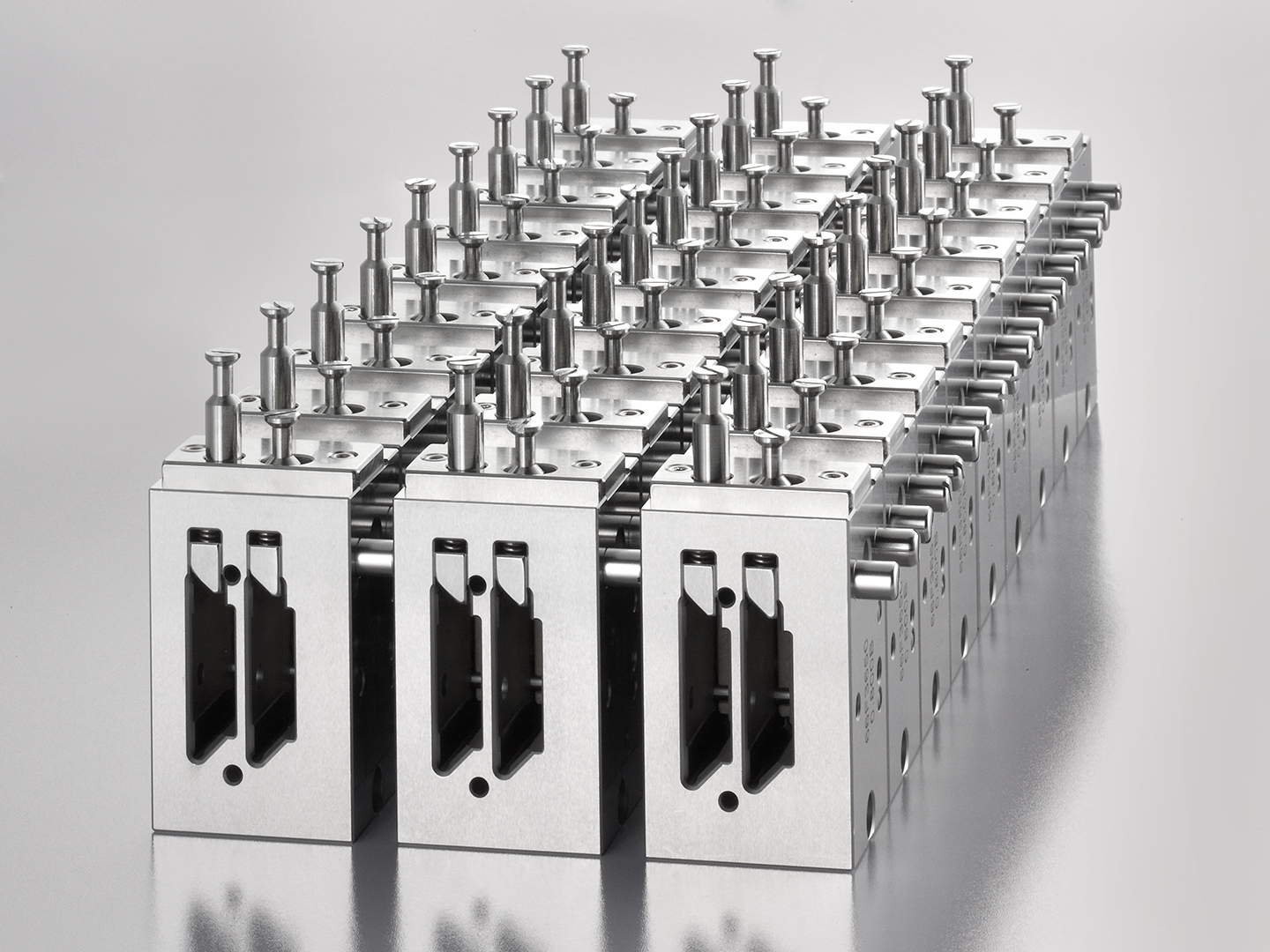

- Industrial products: Metal is used to create a variety of industrial products, such as machinery, tools, and equipment.

- Medical products: Metal is used to create a variety of medical products, such as surgical instruments, implants, and prosthetics.

- Transportation products: Metal is used to create a variety of transportation products, such as cars, trains, and airplanes.

Materials and Techniques Used in Creative Metalworking

In creative metalworking, the choice of materials and techniques plays a crucial role in shaping the final product’s aesthetic appeal and functionality. Various metals possess unique properties that cater to specific design requirements, while fabrication techniques enable artisans to transform these materials into intricate and expressive forms.

Types of Metals

Common metals used in creative metalworking include:

- Steel:Durable, strong, and versatile, steel is an alloy of iron and carbon. It offers a range of grades and finishes, making it suitable for a wide array of applications.

- Aluminum:Lightweight, corrosion-resistant, and highly malleable, aluminum is ideal for intricate designs and applications where weight is a concern.

- Copper:Known for its warm, reddish hue, copper is ductile, malleable, and an excellent conductor of heat and electricity.

- Brass:An alloy of copper and zinc, brass offers a golden color and is resistant to corrosion, making it a popular choice for decorative items and musical instruments.

- Bronze:An alloy of copper and tin, bronze is strong, durable, and has a distinctive reddish-brown color.

Fabrication Techniques

Various fabrication techniques are employed to shape and join metals, including:

- Welding:A process that fuses metal pieces together using heat, creating a permanent bond.

- Forging:Heating metal to a high temperature and hammering it into desired shapes.

- Casting:Pouring molten metal into a mold to create complex forms.

Design Considerations for Creative Metal Products

When creating creative metal products, it’s crucial to consider various design principles and factors to ensure both functionality and aesthetics. These include aspects such as material selection, structural integrity, surface treatments, and the overall form and shape of the product.

Functionality

Functionality is paramount in creative metal products. The design should prioritize the intended use and purpose of the product. Consider factors such as:

- Load-bearing capacity

- Durability and longevity

- Ergonomics and user comfort

- Ease of assembly and maintenance

Aesthetics

Aesthetics play a significant role in the appeal of creative metal products. The design should complement the product’s functionality while enhancing its visual appeal. Consider factors such as:

- Surface finishes and textures

- Color and patination

- Form and shape

- Integration of decorative elements

Durability

Durability is essential for creative metal products, especially those intended for outdoor use or heavy-duty applications. Consider factors such as:

- Material thickness and strength

- Corrosion resistance

- Weather resistance

- Load-bearing capacity

Industry Trends and Innovations in Creative Metalworking

The creative metalworking industry is constantly evolving, with new technologies and materials emerging all the time. These innovations are shaping the future of metalworking, enabling designers and manufacturers to create products that are more complex, durable, and beautiful than ever before.

One of the most significant trends in creative metalworking is the use of 3D printing. This technology allows designers to create complex shapes and geometries that would be impossible to produce using traditional manufacturing methods. 3D printing is also used to create prototypes and models, which can save time and money during the product development process.

New Technologies and Materials, Creative metal products

Several new technologies and materials are being used in creative metalworking, including:

- 3D printing:This technology allows designers to create complex shapes and geometries that would be impossible to produce using traditional manufacturing methods.

- Laser cutting:This technology uses a laser to cut metal with precision and accuracy. Laser cutting can be used to create intricate designs and patterns.

- Waterjet cutting:This technology uses a high-pressure water jet to cut metal. Waterjet cutting can be used to create precise cuts in a variety of materials.

- Plasma cutting:This technology uses a plasma torch to cut metal. Plasma cutting can be used to cut thick materials quickly and efficiently.

- Powder coating:This technology uses a powder coating to create a durable and attractive finish on metal products.

These technologies and materials are enabling designers and manufacturers to create products that are more complex, durable, and beautiful than ever before.

Benefits and Challenges

The use of new technologies and materials in creative metalworking offers several benefits, including:

- Increased design flexibility:New technologies allow designers to create complex shapes and geometries that would be impossible to produce using traditional manufacturing methods.

- Improved accuracy and precision:New technologies, such as laser cutting and waterjet cutting, can cut metal with precision and accuracy. This is essential for creating products that meet exacting specifications.

- Increased durability:New materials, such as powder coating, can create a durable and attractive finish on metal products.

- Reduced costs:New technologies, such as 3D printing, can reduce the cost of producing prototypes and models.

However, there are also some challenges associated with the use of new technologies and materials in creative metalworking, including:

- High cost:Some new technologies, such as 3D printing, can be expensive to purchase and operate.

- Complexity:Some new technologies, such as laser cutting and waterjet cutting, require specialized training to operate.

- Limited availability:Some new technologies and materials are not widely available.

Despite these challenges, the use of new technologies and materials in creative metalworking is expected to continue to grow in the coming years. These technologies and materials are enabling designers and manufacturers to create products that are more complex, durable, and beautiful than ever before.

Future of Creative Metalworking

The future of creative metalworking is bright. New technologies and materials are emerging all the time, which is enabling designers and manufacturers to create products that are more complex, durable, and beautiful than ever before.

Some of the trends that are expected to continue in the future of creative metalworking include:

- Increased use of 3D printing:3D printing is expected to become more affordable and accessible in the coming years, which will make it even more popular for prototyping, modeling, and production.

- Development of new materials:New materials are being developed all the time that are stronger, lighter, and more durable than traditional materials. These new materials will enable designers and manufacturers to create products that are even more innovative and functional.

- Increased use of automation:Automation is expected to play a larger role in creative metalworking in the future. This will help to reduce costs and improve efficiency.

The future of creative metalworking is full of possibilities. New technologies and materials are emerging all the time, which is enabling designers and manufacturers to create products that are more complex, durable, and beautiful than ever before.

Sustainability in Creative Metalworking

The creative metalworking industry has a significant environmental impact due to the energy-intensive processes and materials used. However, there is a growing movement towards sustainable practices to mitigate this impact.Sustainable metalworking involves using eco-friendly materials, reducing waste, and implementing energy-efficient processes.

Recycled metals, such as aluminum and steel, have a lower environmental footprint than virgin materials. Biodegradable materials like bamboo and cork are also gaining popularity.

Sustainable Practices

* Using renewable energy sources to power metalworking operations

Creating unique metal products involves artistic vision and technical expertise. To enhance your creativity, consider exploring creative curriculum studies. This field offers insights into fostering innovation, nurturing imagination, and developing problem-solving skills. By integrating these concepts into your metalworking practice, you’ll unlock new possibilities and create exceptional metal products that captivate and inspire.

- Implementing water conservation measures to reduce water consumption

- Recycling metal scraps and waste to minimize landfill waste

- Employing eco-friendly surface treatments and finishes

- Promoting sustainable packaging and shipping practices

Environmental Impact Mitigation

* Reducing greenhouse gas emissions by optimizing energy efficiency

- Minimizing air pollution through the use of proper ventilation systems

- Preventing water pollution by treating wastewater before releasing it into the environment

- Conserving natural resources by using sustainable materials and recycling

- Educating metalworkers and consumers about sustainable practices

Collaboration and Partnerships in Creative Metalworking

In the realm of creative metalworking, collaboration is paramount. Successful products emerge from the harmonious interplay of designers, engineers, and artisans, each bringing their unique expertise to the table.

Designers envision the aesthetic appeal and functionality of the product, while engineers ensure its structural integrity and manufacturability. Artisans, with their mastery of traditional and contemporary metalworking techniques, bring the design to life, transforming raw materials into objects of beauty and utility.

Successful Partnerships

Numerous examples showcase the transformative power of collaboration in creative metalworking. One notable partnership is that between Zaha Hadid Architects and Arup, a global engineering and design firm.

- Their collaboration on the Heydar Aliyev Center in Baku, Azerbaijan, resulted in a striking architectural masterpiece featuring a complex, fluid form made possible by innovative metalworking techniques.

– Provide a brief overview of the industry landscape for creative metal products.

The industry landscape for creative metal products is characterized by a growing demand for unique and innovative designs, driven by the increasing popularity of custom interiors and architectural elements. This demand is further fueled by technological advancements that have expanded the possibilities for metalworking, enabling the creation of complex and intricate designs.

The industry is also witnessing a shift towards sustainable practices, with a focus on reducing environmental impact and promoting resource efficiency. This has led to the adoption of eco-friendly materials and processes, such as recycled metals and energy-efficient production techniques.

Marketing and Promotion of Creative Metal Products

Effectively marketing and promoting creative metal products is crucial for success in this competitive industry. By understanding target audiences and highlighting unique value propositions, businesses can effectively promote their products and reach the right customers.

To effectively target specific audiences, businesses should conduct thorough market research to identify their demographics, interests, and purchasing behaviors. This information can be used to develop tailored marketing campaigns that resonate with the target audience and increase conversion rates.

Highlighting Unique Value Proposition

Creative metal products often possess unique characteristics that set them apart from mass-produced items. These unique features should be emphasized in marketing and promotional materials to capture the attention of potential customers. By showcasing the craftsmanship, durability, and aesthetic appeal of these products, businesses can differentiate their offerings and establish a competitive advantage.

Online Marketing

In today’s digital age, online marketing plays a significant role in promoting creative metal products. Social media platforms, search engine optimization (), and email marketing can be leveraged to reach a wider audience and generate leads. Businesses should create engaging content that showcases the products’ unique features and provides valuable information to potential customers.

Trade Shows and Events

Trade shows and industry events offer an excellent opportunity to connect with potential customers and showcase creative metal products. By participating in these events, businesses can demonstrate their products in person, network with industry professionals, and generate new sales leads.

Collaborations and Partnerships

Collaborating with other businesses or influencers can be an effective way to reach new audiences and promote creative metal products. By partnering with complementary businesses or individuals with a strong following, businesses can leverage their networks and credibility to increase brand awareness and generate sales.

Pricing and Distribution of Creative Metal Products

Pricing and distribution are crucial aspects of marketing creative metal products. Understanding the factors that influence pricing and the various distribution channels available can help businesses optimize their revenue and reach their target audience.

Pricing strategies for creative metal products consider factors such as material costs, labor expenses, market demand, and perceived value. The materials used, including their quality and rarity, significantly impact the cost of production. Labor costs vary depending on the complexity of the design and the skill level of the craftsperson.

Market demand and competition also play a role in determining the appropriate price point.

Distribution Channels

Distribution channels for creative metal products range from direct sales to retail stores, online marketplaces, and wholesale distributors. Direct sales involve selling directly to customers through the business’s website or physical store. Retail stores offer a wider reach but may have limitations in terms of product selection and customization options.

Online marketplaces provide a global platform for reaching a large audience but may involve competition and platform fees. Wholesale distributors purchase products in bulk and resell them to other businesses, offering economies of scale and access to a wider distribution network.

Legal and Ethical Considerations in Creative Metalworking

In creative metalworking, legal and ethical considerations are essential to ensure the protection of intellectual property, safety, and the environment. Understanding these considerations helps metalworkers navigate the industry responsibly and avoid potential risks.

Intellectual Property

Creative metalworking involves the creation of original designs, which can be protected under intellectual property laws. These laws include:

- Copyright: Protects artistic expression, such as designs, sketches, and prototypes.

- Trademark: Protects distinctive signs, such as logos, symbols, and brand names.

- Patent: Protects inventions and new processes, including innovative metalworking techniques.

It is crucial to obtain the necessary licenses and permits before using copyrighted, trademarked, or patented materials in creative metalworking.

Safety Regulations

Metalworking involves the use of tools, equipment, and materials that pose potential safety hazards. To ensure a safe work environment, it is essential to comply with safety regulations, such as:

- Occupational Safety and Health Administration (OSHA): Sets standards for workplace safety, including the use of personal protective equipment (PPE) and proper ventilation.

- National Fire Protection Association (NFPA): Establishes codes and standards for fire prevention and control in metalworking facilities.

Adhering to safety regulations helps prevent accidents and injuries.

Environmental Compliance

Creative metalworking can impact the environment through waste disposal and emissions. It is important to comply with environmental regulations, such as:

- Resource Conservation and Recovery Act (RCRA): Regulates the disposal of hazardous waste, including metal scraps and chemicals.

- Clean Air Act (CAA): Sets standards for air emissions, including those from welding and metalworking processes.

By following environmental regulations, metalworkers contribute to protecting the planet.

Resources for Legal and Ethical Considerations

- U.S. Patent and Trademark Office (USPTO): Provides information on intellectual property protection.

- OSHA: Offers resources on workplace safety regulations.

- Environmental Protection Agency (EPA): Provides guidance on environmental compliance for metalworking facilities.

Career Opportunities in Creative Metalworking

The creative metalworking industry offers diverse career paths for individuals with a passion for metalworking and creativity. This field encompasses a wide range of roles, from skilled artisans to engineers and designers.

To succeed in creative metalworking, a strong foundation in metalworking techniques, design principles, and industry knowledge is essential. Various educational programs and apprenticeships provide the necessary skills and qualifications.

Job Roles and Responsibilities

- Metal Fabricator:Cuts, shapes, and assembles metal components using hand and power tools.

- Welder:Joins metal pieces together using various welding techniques, ensuring structural integrity.

- Metal Artist:Creates unique and artistic metal pieces using a combination of traditional and contemporary techniques.

- Industrial Designer:Designs and develops functional and aesthetically pleasing metal products, considering factors such as ergonomics, safety, and manufacturability.

- Mechanical Engineer:Analyzes, designs, and develops metal structures and components, ensuring their strength, durability, and performance.

These roles often involve collaboration with other professionals, such as architects, engineers, and designers, to bring creative metalworking projects to life.

Education and Training in Creative Metalworking

Aspiring creative metalworkers have various educational programs and training opportunities available to develop their skills and knowledge.

Hands-on experience is crucial for developing proficiency in creative metalworking. Mentorship from experienced professionals can provide invaluable guidance and support.

Educational Programs

- Associate’s Degree in Metalworking:Provides a foundation in metalworking techniques, design principles, and safety practices.

- Bachelor’s Degree in Fine Arts (with a concentration in Metalworking):Focuses on developing artistic and technical skills, including advanced metalworking techniques and design.

- Master’s Degree in Metalworking:Advanced studies in metalworking, research, and design innovation.

Training Opportunities

- Apprenticeships:Hands-on training under the supervision of experienced metalworkers.

- Workshops and Classes:Short-term programs covering specific metalworking techniques, such as welding, forging, or casting.

- Online Courses:Provide flexibility and accessibility to learning metalworking basics.

– Future Outlook for Creative Metalworking

The future of creative metalworking holds immense promise, driven by technological advancements and evolving market demands. Emerging technologies, such as additive manufacturing, artificial intelligence (AI), and robotics, are poised to revolutionize the industry, enabling the creation of innovative and highly customized products.

Additive manufacturing, also known as 3D printing, allows for the fabrication of complex geometries that were previously impossible to produce using traditional methods. This technology opens up new possibilities for product design, enabling the creation of intricate and lightweight structures with enhanced functionality.

AI is transforming the design and manufacturing processes in creative metalworking. AI algorithms can analyze vast amounts of data to optimize designs, predict material behavior, and automate repetitive tasks. This leads to increased efficiency, reduced costs, and improved product quality.

Robotics is another key technology that is revolutionizing the industry. Robotic systems can perform tasks with precision and efficiency, freeing up human workers to focus on more complex and creative aspects of the process. This collaboration between humans and robots enables the production of high-quality products with shorter lead times.

Market Trends and Challenges

The demand for customized products is growing rapidly across various industries, including architecture, automotive, and consumer goods. This trend is driving the growth of creative metalworking, as businesses seek unique and tailored solutions to meet their specific needs.

However, the industry also faces challenges, such as the rising cost of raw materials and skilled labor. To address these challenges, businesses are exploring innovative approaches, such as using recycled materials and investing in workforce development programs.

Sustainability is becoming increasingly important in creative metalworking. Manufacturers are adopting eco-friendly practices to reduce their environmental impact. This includes using sustainable materials, implementing energy-efficient processes, and minimizing waste.

Collaboration and Partnerships

Collaboration and partnerships are essential for the advancement of creative metalworking. Businesses are forming alliances with research institutions, design firms, and other industry players to share knowledge, resources, and expertise. These collaborations foster innovation and lead to the development of groundbreaking products.

Conclusion

The future of creative metalworking is bright. With the advent of new technologies, the growing demand for customized products, and the focus on sustainability, the industry is poised for continued growth and innovation. By embracing emerging technologies, addressing challenges, and fostering collaboration, creative metalworkers can unlock new possibilities and shape the future of manufacturing.

FAQ Insights: Creative Metal Products

What are the most common types of metals used in creative metal products?

Steel, aluminum, stainless steel, copper, and brass are commonly used for their strength, durability, and aesthetic appeal.

What are the key design considerations for creative metal products?

Form, function, aesthetics, material properties, and fabrication techniques are crucial factors to consider when designing creative metal products.

What are some innovative applications of creative metal products?

Creative metal products find applications in architecture, interior design, furniture, sculptures, and even wearable art.