Step into the realm of creative liquid coatings, where artistry meets functionality. These innovative coatings transcend traditional boundaries, unlocking a world of possibilities for industries seeking enhanced aesthetics, durability, and performance.

From sleek automotive finishes to corrosion-resistant aerospace components, creative liquid coatings are redefining the way we protect and beautify surfaces. Join us as we explore the captivating world of these coatings, their applications, and the transformative impact they’re making across various sectors.

Definition of Creative Liquid Coatings

Creative liquid coatings are innovative materials that offer unique properties and design possibilities beyond traditional coatings. These coatings are formulated with special additives, pigments, and binders to create visually striking effects, textures, and functionalities.

Their versatility allows for applications in diverse industries, including automotive, architecture, fashion, and consumer products.

Unique Properties and Characteristics

- Exceptional Aesthetics:Create eye-catching colors, patterns, and textures that enhance visual appeal.

- Functional Enhancements:Provide properties such as anti-fouling, antimicrobial, or self-cleaning capabilities.

- Durability and Longevity:Formulated to withstand wear and tear, ensuring long-lasting performance.

Potential Applications

- Automotive:Enhance vehicle aesthetics, protect surfaces, and improve fuel efficiency.

- Architecture:Create visually stunning facades, interior finishes, and decorative elements.

- Fashion:Add color, texture, and functionality to textiles, accessories, and footwear.

- Consumer Products:Enhance the appearance and durability of electronics, appliances, and home decor.

Types of Creative Liquid Coatings

Creative liquid coatings encompass a diverse range of coatings designed to enhance the aesthetics, functionality, and durability of surfaces. These coatings offer a myriad of options, each with unique properties and applications.

Composition and Properties

Creative liquid coatings are typically composed of a combination of resins, pigments, solvents, and additives. The composition determines the coating’s properties, such as adhesion, flexibility, hardness, and chemical resistance.

Types of Coatings

The types of creative liquid coatings include:

Metallic Coatings

Contain metallic pigments to create a lustrous, reflective finish.

Pearlescent Coatings

Exhibit an iridescent effect due to the presence of mica or other light-interfering pigments.

Fluorescent Coatings

Absorb ultraviolet light and emit visible light, creating a vibrant glow.

Photochromic Coatings

Change color in response to light, such as sunlight or UV radiation.

Phosphorescent Coatings

Store energy from light and release it as a faint glow in the dark.

Textured Coatings

Create a tactile or textured surface with the addition of particles or fibers.

Antimicrobial Coatings

Inhibit the growth of bacteria and other microorganisms.

Self-Cleaning Coatings

Repel water and dirt, making surfaces easier to clean.

Applications

Creative liquid coatings find applications in various industries, including:

Automotive

Enhance the appearance and durability of vehicles.

Architecture

Protect and beautify buildings and structures.

Consumer Electronics

Provide scratch and corrosion resistance to electronic devices.

Aerospace

Create lightweight and protective coatings for aircraft.

Healthcare

Develop antimicrobial surfaces for hospitals and medical equipment.

Table of Key Characteristics

| Coating Type | Composition | Properties | Applications ||—|—|—|—|| Metallic | Metallic pigments | Reflective, lustrous | Automotive, architecture || Pearlescent | Mica or light-interfering pigments | Iridescent effect | Cosmetics, packaging || Fluorescent | UV-absorbing pigments | Vibrant glow | Signage, safety markings || Photochromic | Light-sensitive pigments | Color change in response to light | Sunglasses, architectural glazing || Phosphorescent | Energy-storing pigments | Faint glow in the dark | Safety equipment, toys || Textured | Particles or fibers | Tactile or textured surface | Decorative finishes, anti-slip coatings || Antimicrobial | Antimicrobial agents | Inhibit microbial growth | Hospitals, healthcare equipment || Self-Cleaning | Water- and dirt-repellent additives | Easy cleaning | Buildings, automotive surfaces |

Latest Advancements and Trends

Ongoing advancements in creative liquid coatings include:

- Development of eco-friendly coatings with reduced VOC emissions.

- Research on self-healing coatings that can repair damage autonomously.

- Exploration of nanotechnology to create coatings with enhanced properties.

- Integration of smart coatings with sensors and actuators for interactive surfaces.

Applications of Creative Liquid Coatings

Creative liquid coatings are finding applications in a wide range of industries, including:

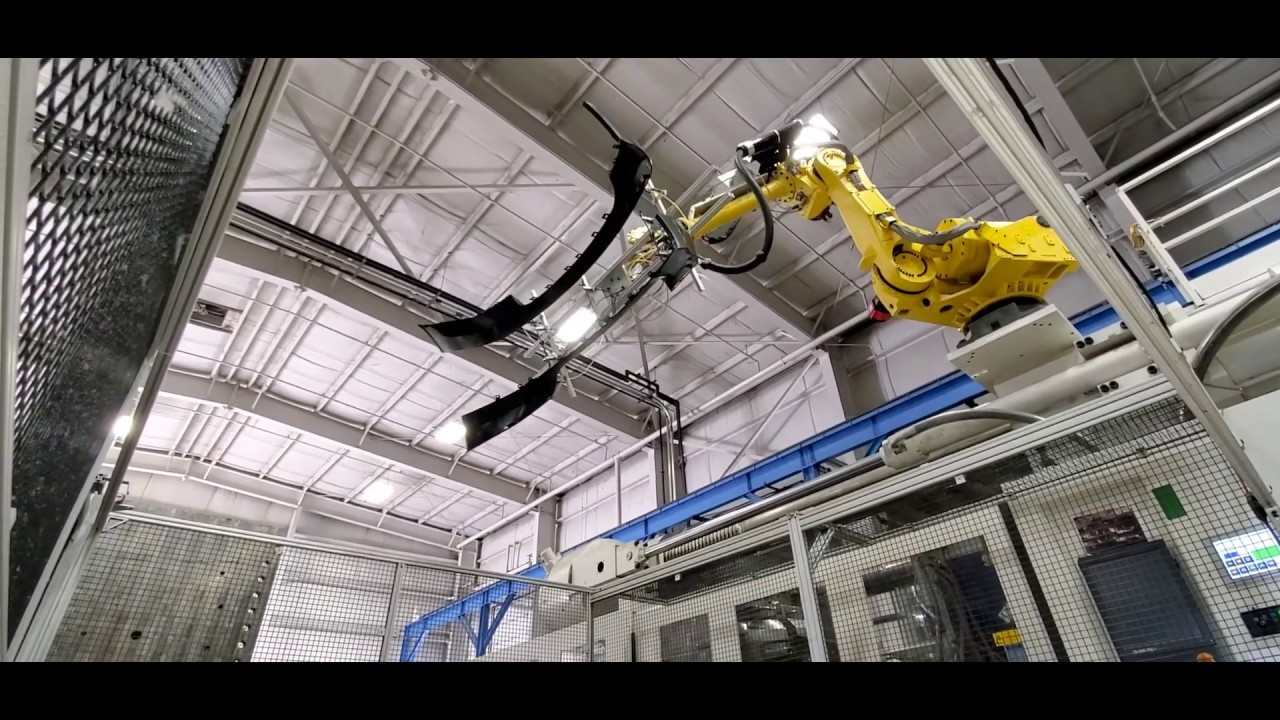

Automotive

- Enhanced durability and corrosion resistance for vehicle exteriors

- Improved aesthetics with custom colors, finishes, and textures

- Increased functionality with anti-fouling and self-cleaning properties

- Example: A leading car manufacturer used a creative liquid coating to create a unique matte finish on a limited-edition sports car, enhancing its visual appeal and exclusivity.

Aerospace

- Improved durability and corrosion resistance for aircraft components

- Enhanced aesthetics with lightweight and reflective coatings

- Increased functionality with anti-icing and radar-absorbing properties

- Example: A major aerospace company applied a creative liquid coating to reduce ice accumulation on aircraft wings, improving flight safety and efficiency.

Construction

- Enhanced durability and protection for building exteriors

- Improved aesthetics with decorative and textured finishes

- Increased functionality with fire-resistant, water-repellent, and self-cleaning properties

- Example: A construction firm used a creative liquid coating to create a water-repellent facade on a high-rise building, reducing maintenance costs and improving the building’s longevity.

Medical, Creative liquid coatings

- Improved biocompatibility and durability for medical devices

- Enhanced functionality with drug-delivery and antimicrobial properties

- Increased patient comfort with soft and flexible coatings

- Example: A medical device manufacturer developed a creative liquid coating for a heart valve that improved its biocompatibility, reducing the risk of rejection.

Electronics

- Improved durability and protection for electronic components

- Enhanced functionality with conductive and insulating properties

- Increased performance with heat dissipation and electromagnetic interference shielding

- Example: An electronics company used a creative liquid coating to create a conductive coating on a circuit board, improving its performance and reducing its size.

Methods for Applying Creative Liquid Coatings

Applying creative liquid coatings requires careful preparation and technique to achieve optimal results. Several methods can be employed, each with its advantages and considerations.

Brush Application

Brush application is a traditional method that offers precise control over the coating’s thickness and placement. Use a high-quality brush designed for the specific coating being used. Apply the coating in even strokes, working from one end to the other.

Allow each coat to dry thoroughly before applying the next.

Roller Application

Roller application is suitable for larger surfaces and provides a more consistent finish. Use a roller with a nap size appropriate for the coating’s viscosity. Apply the coating in overlapping strokes, rolling in one direction to avoid streaks. Remove excess coating by rolling over the surface with light pressure.

Spray Application

Spray application is ideal for complex shapes or hard-to-reach areas. Use a spray gun with the correct nozzle size and pressure settings for the coating being used. Apply the coating in thin, even coats, holding the gun perpendicular to the surface.

Allow each coat to flash off before applying the next.

Dip Application

Dip application involves immersing the object in the coating. This method provides a uniform coating thickness and is suitable for complex shapes. Prepare the object by cleaning and drying it thoroughly. Submerge the object in the coating, ensuring it is completely covered.

Remove the object and allow the excess coating to drain.

Electrostatic Spray Application

Electrostatic spray application uses a high-voltage charge to attract the coating particles to the surface. This method provides excellent coverage and adhesion, especially on metal surfaces. Use a specialized electrostatic spray gun and follow the manufacturer’s instructions carefully.

Design Considerations for Creative Liquid Coatings

Crafting effective creative liquid coatings involves thoughtful design considerations. Here are key principles and guidelines to optimize their appearance and functionality:

Surface Preparation

Proper surface preparation is crucial. The substrate’s surface should be clean, dry, and free of contaminants to ensure optimal adhesion and coating performance.

Coating Thickness

The thickness of the coating affects its durability, appearance, and functionality. Thinner coatings provide flexibility and transparency, while thicker coatings offer enhanced protection and opacity.

Pigment Selection

The choice of pigments determines the color, opacity, and reflectivity of the coating. Consider factors such as lightfastness, durability, and chemical resistance when selecting pigments.

Additives

Additives can enhance specific properties of the coating, such as adhesion, flexibility, or water resistance. Careful selection of additives is essential to achieve the desired performance characteristics.

Application Method

The application method influences the coating’s appearance and functionality. Spraying, brushing, or dipping can produce different textures and effects.

Curing Process

The curing process affects the coating’s hardness, durability, and chemical resistance. Proper curing ensures optimal performance and longevity.

Environmental Considerations

Consider the environmental impact of the coating materials and application processes. Opt for eco-friendly options to minimize environmental footprint.

Sustainability and Environmental Impact of Creative Liquid Coatings

Creative liquid coatings have a varied environmental impact, depending on their composition and application methods. Some coatings are designed to be eco-friendly and biodegradable, while others may contain harmful chemicals or require energy-intensive processes to apply.

Bring your surfaces to life with creative liquid coatings! Unleash your inner creative soul and experiment with colors, textures, and effects. Transform ordinary objects into masterpieces, expressing your unique style. Creative liquid coatings empower you to create visually stunning and durable surfaces that reflect your creativity.

Eco-friendliness and Biodegradability

Eco-friendly coatings are formulated using renewable or plant-based materials, reducing their environmental footprint. Biodegradable coatings can break down naturally over time, minimizing waste and pollution. These coatings often use water-based solvents, which are less harmful to the environment than traditional organic solvents.

Disposal Methods

Proper disposal of creative liquid coatings is crucial to minimize environmental impact. Some coatings can be disposed of in regular landfills, while others may require specialized disposal methods, such as incineration or chemical treatment. It is important to follow manufacturer’s guidelines for proper disposal to prevent contamination or harm to the environment.

Trends and Innovations in Creative Liquid Coatings

The field of creative liquid coatings is constantly evolving, with new trends and innovations emerging all the time. These advancements are driven by the need for coatings that are more durable, more versatile, and more sustainable.

One of the most significant trends in the creative liquid coatings industry is the development of new materials and formulations. These new materials are enabling the creation of coatings with new functionalities and effects. For example, some new coatings are self-cleaning, while others are able to change color or pattern in response to external stimuli.

Another major trend is the integration of smart technologies and sensors into liquid coatings. These smart coatings can be used to create interactive surfaces that can respond to touch, light, or other environmental cues. This technology has the potential to revolutionize the way we interact with our surroundings.

Sustainability is also a major concern for the creative liquid coatings industry. Manufacturers are increasingly developing coatings that are more environmentally friendly and have a lower impact on the environment.

These trends and innovations are having a transformative impact on the creative liquid coatings industry. They are enabling the creation of new and innovative products that are more durable, more versatile, and more sustainable.

Advancements in Materials and Formulations

The development of new materials and formulations is one of the most significant trends in the creative liquid coatings industry. These new materials are enabling the creation of coatings with new functionalities and effects.

- Self-cleaning coatings: These coatings are designed to repel dirt and water, making them ideal for use on surfaces that are exposed to the elements.

- Antimicrobial coatings: These coatings are designed to kill bacteria and other microorganisms, making them ideal for use in hospitals and other healthcare settings.

- Conductive coatings: These coatings are designed to conduct electricity, making them ideal for use in electronic devices.

- Thermochromic coatings: These coatings are designed to change color in response to changes in temperature, making them ideal for use in temperature-sensitive applications.

- Photochromic coatings: These coatings are designed to change color in response to changes in light, making them ideal for use in sunglasses and other light-sensitive applications.

Integration of Smart Technologies and Sensors

The integration of smart technologies and sensors into liquid coatings is another major trend in the creative liquid coatings industry. These smart coatings can be used to create interactive surfaces that can respond to touch, light, or other environmental cues.

- Touch-sensitive coatings: These coatings can be used to create interactive surfaces that can be controlled by touch.

- Light-sensitive coatings: These coatings can be used to create interactive surfaces that can respond to changes in light.

- Temperature-sensitive coatings: These coatings can be used to create interactive surfaces that can respond to changes in temperature.

- Motion-sensitive coatings: These coatings can be used to create interactive surfaces that can respond to movement.

- Chemical-sensitive coatings: These coatings can be used to create interactive surfaces that can respond to changes in the chemical environment.

Sustainability and Environmental Impact

Sustainability is also a major concern for the creative liquid coatings industry. Manufacturers are increasingly developing coatings that are more environmentally friendly and have a lower impact on the environment.

- Water-based coatings: These coatings are made with water instead of solvents, which makes them more environmentally friendly.

- Low-VOC coatings: These coatings have a low VOC (volatile organic compound) content, which makes them less harmful to the environment.

- Recyclable coatings: These coatings can be recycled, which reduces their environmental impact.

- Biodegradable coatings: These coatings are made from biodegradable materials, which means they can break down naturally in the environment.

Examples of Creative Liquid Coatings

Creative liquid coatings are gaining prominence in various industries, transforming surfaces with unique properties and aesthetic appeal. Here are some real-world examples that showcase their effectiveness:

Automotive Industry

In the automotive industry, creative liquid coatings enhance vehicle aesthetics and performance:

- Self-healing coatings:Protect against scratches and minor damage, maintaining the vehicle’s pristine appearance.

- Anti-fouling coatings:Prevent dirt, debris, and ice accumulation, improving aerodynamics and fuel efficiency.

- Hydrophobic coatings:Repel water and contaminants, making vehicles easier to clean and reducing corrosion.

Construction Industry

Creative liquid coatings provide functional and aesthetic benefits in construction:

- Antimicrobial coatings:Inhibit the growth of bacteria and mold, improving indoor air quality in hospitals and other public spaces.

- Thermal insulation coatings:Reduce heat loss in buildings, lowering energy consumption and increasing occupant comfort.

- Anti-graffiti coatings:Protect surfaces from vandalism and make them easier to clean.

Medical Industry

Creative liquid coatings play a crucial role in medical applications:

- Antibacterial coatings:Reduce the risk of infections on medical devices and implants.

- Drug-delivery coatings:Control the release of medication over time, improving patient outcomes.

- Biocompatible coatings:Enhance the compatibility of medical implants with the human body, reducing rejection and complications.

Design Table for Creative Liquid Coatings

Creative liquid coatings offer diverse properties and applications, making it essential to compare their characteristics to make informed choices. The following table provides a comprehensive overview of different types of creative liquid coatings, highlighting their properties, applications, advantages, and disadvantages.

By understanding the specific characteristics of each type of coating, designers and manufacturers can optimize their selection based on the desired performance and aesthetic requirements of their projects.

Types of Creative Liquid Coatings

| Type | Properties | Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Thermochromic Coatings | – Change color in response to temperature

| – Temperature-sensing devices

| – Visual indication of temperature changes

| – Limited durability

|

| Photochromic Coatings | – Change color in response to light

| – Sunglasses

| – Protection from UV radiation

| – Can be slow to react

|

| Electroluminescent Coatings | – Emit light when an electric current is applied

| – Lighting

| – Bright and vibrant colors

| – Requires an electrical source

|

| Magnetic Coatings | – Contain magnetic particles

| – Magnetic sensors

| – Magnetic properties

| – Can be heavy

|

| Conductive Coatings | – Conduct electricity

| – Flexible electronics

| – Electrical conductivity

| – Can be expensive For innovative solutions in protective and decorative coatings, explore creative liquid coatings. These advanced coatings offer unique textures, colors, and effects. To find creative agencies in New York City that specialize in design and branding for such coatings, visit creative agencies nyc. Their expertise can help you develop captivating visual identities and marketing campaigns that showcase the exceptional qualities of creative liquid coatings.

|

Process Flowchart for Applying Creative Liquid Coatings

Applying creative liquid coatings involves multiple steps that require precision and quality control. Here’s a flowchart that Artikels the key steps involved:

Step 1: Surface Preparation– Ensure the surface is clean, dry, and free of contaminants. – Remove any rust, dirt, or grease using appropriate cleaning methods.

Step 2: Primer Application (Optional)– Apply a primer if required to enhance adhesion and provide a base layer for the coating.

Step 3: Coating Application– Select the appropriate coating material and application method. – Apply the coating evenly, ensuring proper thickness and coverage.

Step 4: Curing or Drying– Allow the coating to cure or dry according to the manufacturer’s instructions. – This step ensures the coating achieves its desired properties.

Step 5: Quality Control– Inspect the coating for defects, such as bubbles, cracks, or unevenness. – Use appropriate testing methods to verify coating thickness, adhesion, and other performance parameters.

Step 6: Finishing (Optional)– Apply a topcoat or sealant to enhance durability and provide a desired finish.

Provide a detailed case study of a successful application of creative liquid coatings in the automotive industry.

In the automotive industry, creative liquid coatings have gained popularity due to their ability to enhance aesthetics and durability. One notable example is the application of these coatings on the exterior of vehicles to create unique designs and protect against corrosion.

Here’s a detailed case study of a successful application:

Case Study: Custom Automotive Coatings by BASF

BASF, a leading chemical company, developed a range of creative liquid coatings specifically for the automotive industry. These coatings offer a combination of durability, flexibility, and aesthetic appeal. One of their successful applications is on the BMW i8 sports car.

Challenges:

- Creating a unique and eye-catching design for the i8’s exterior.

- Ensuring the coating’s durability to withstand various environmental conditions.

Solutions:

- BASF’s team worked closely with BMW’s designers to develop a custom coating formula that met the desired aesthetic and performance requirements.

- They used a combination of basecoat and clearcoat layers, each with specific properties to enhance durability and appearance.

Outcomes:

- The BMW i8 featured a striking blue exterior with a metallic finish, created using BASF’s creative liquid coatings.

- The coatings provided excellent protection against corrosion, UV rays, and other environmental factors.

- The vehicle’s exterior maintained its vibrant color and finish even after prolonged use.

Benefits of Creative Liquid Coatings in the Automotive Industry:

- Enhanced aesthetics and customization options.

- Improved durability and corrosion resistance.

- Protection against UV rays and other environmental factors.

- Lightweight and flexible, allowing for complex designs.

Limitations:

- Can be more expensive than traditional coatings.

- Application requires specialized equipment and expertise.

Recommendations for Future Applications and Research Directions:

- Exploring new formulations to further enhance durability and performance.

- Developing self-healing coatings to minimize maintenance and repair costs.

- Investigating sustainable and eco-friendly coating materials.

Comparison of Creative Liquid Coatings to Traditional Coatings

Creative liquid coatings (CLCs) and traditional coatings share similarities as surface treatments that provide protection and enhance aesthetics. However, they also have distinct differences.Traditional coatings are typically formulated with solvents, resins, and pigments, and applied in multiple layers to achieve desired properties.

They offer durability, resistance to wear and corrosion, and can be customized in terms of color and texture. However, traditional coatings can be limited in terms of flexibility, transparency, and ability to create complex patterns or textures.CLCs, on the other hand, are formulated with advanced materials such as polymers, nanoparticles, and functional additives, and can be applied in a single layer.

They offer unique properties such as high flexibility, transparency, and the ability to create complex patterns and textures. CLCs can also be formulated to be self-cleaning, anti-fouling, or responsive to external stimuli.

Advantages of Creative Liquid Coatings over Traditional Coatings

Versatility

CLCs offer greater versatility in terms of design and functionality, enabling the creation of surfaces with unique patterns, textures, and properties.

Durability

CLCs can provide comparable or even better durability compared to traditional coatings, while maintaining flexibility and transparency.

Sustainability

CLCs can be formulated using environmentally friendly materials and processes, reducing the environmental impact of coating applications.

Advantages of Traditional Coatings over Creative Liquid Coatings

Cost

Traditional coatings are generally more cost-effective than CLCs, especially for large-scale applications.

Proven Performance

Traditional coatings have a long history of proven performance and reliability in various industries.

Wide Availability

Traditional coatings are widely available and supported by a mature supply chain.Ultimately, the choice between CLCs and traditional coatings depends on the specific requirements of the application. CLCs offer unique advantages for applications requiring high flexibility, transparency, or complex designs, while traditional coatings remain a cost-effective and reliable option for many general-purpose applications.

Troubleshooting Guide for Creative Liquid Coatings

Working with creative liquid coatings can be a rewarding experience, but it’s not without its challenges. To help you achieve optimal results, here’s a troubleshooting guide for common problems encountered when using creative liquid coatings:

This guide covers various issues, including application, drying, curing, and other common problems. By understanding the causes and solutions to these issues, you can ensure a successful application of creative liquid coatings.

Application Issues

- Uneven application:This can be caused by improper mixing, incorrect application techniques, or using the wrong equipment. Ensure proper mixing, use the correct application method for the specific coating, and check equipment compatibility.

- Bubbles:Bubbles can form due to trapped air during application. Use a vacuum chamber to remove air before applying, stir the coating gently to avoid introducing air, and apply thin layers to prevent bubbles from forming.

- Streaks:Streaks can occur when the coating is applied too thickly or unevenly. Apply thin, even layers, use a smooth applicator, and maintain a consistent application speed.

Resources and Further Reading on Creative Liquid Coatings

Explore additional resources to delve deeper into the world of creative liquid coatings. These articles, books, and websites offer valuable insights and up-to-date information on various aspects of this innovative technology.

Reputable Sources for Information

- Creative Liquid Coatings: A Comprehensive Guideby the American Coatings Association: This comprehensive resource provides a detailed overview of creative liquid coatings, their types, applications, and industry trends.

- Liquid Coatings: Science and Technologyby S.K. Sharma and M. Singh: This book offers a scientific and technical perspective on liquid coatings, including their formulation, characterization, and performance.

- Coatings World Magazine: This industry publication features articles, news, and insights on the latest developments in the coatings industry, including creative liquid coatings.

- Society for Protective Coatings: This professional organization provides access to technical papers, conferences, and other resources related to coatings technology.

FAQ Section

What are the unique properties of creative liquid coatings?

Creative liquid coatings offer exceptional durability, corrosion resistance, and flexibility, making them ideal for demanding applications.

How are creative liquid coatings applied?

Application methods vary depending on the type of coating and substrate, including spraying, dipping, or brushing.

What are the environmental implications of creative liquid coatings?

Many creative liquid coatings are formulated with eco-friendly materials and comply with environmental regulations.