Welcome to the realm of creative fabrication, where innovation and artistry collide to create a transformative force in the world of design. This cutting-edge field is revolutionizing industries, empowering artists, and reshaping our built environment. Join us as we delve into the captivating world of creative fabrication, exploring its techniques, applications, and the boundless possibilities it holds for the future.

From 3D printing to laser cutting, creative fabrication empowers designers, engineers, and artists to bring their visions to life with unparalleled precision and efficiency. It’s not just about creating objects; it’s about pushing the boundaries of what’s possible, fostering collaboration, and driving sustainable practices.

Dive in and discover the transformative power of creative fabrication!

Creative Fabrication Technologies

Creative fabrication technologies are innovative techniques that enable the creation of complex and customized objects with high precision and efficiency. These technologies have revolutionized the design and manufacturing industries, allowing for the production of intricate parts, prototypes, and finished products.

Among the most significant creative fabrication technologies are 3D printing, laser cutting, and CNC machining.

3D Printing

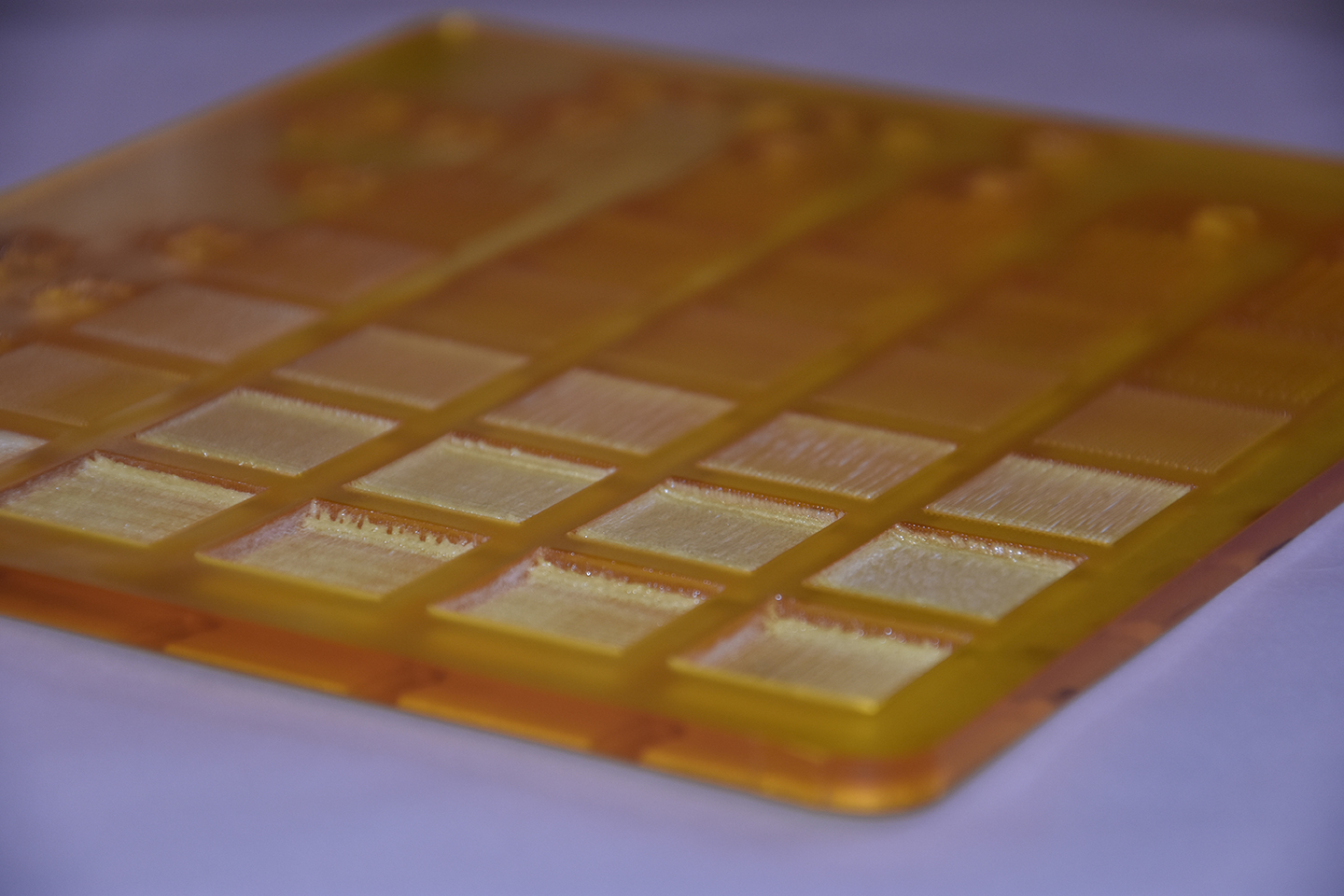

3D printing, also known as additive manufacturing, involves building objects by depositing layers of material, typically plastic or metal, until the desired shape is formed. This technology allows for the creation of complex geometries and intricate designs that would be difficult or impossible to produce using traditional manufacturing methods.

3D printing has a wide range of applications, including prototyping, rapid manufacturing, and the production of custom-made parts for various industries such as automotive, aerospace, and healthcare.

Laser Cutting

Laser cutting is a process that uses a high-powered laser to cut or engrave materials. It offers precise and clean cuts, with minimal heat-affected zones and burrs. Laser cutting is commonly used in the fabrication of sheet metal, plastics, and other materials.

This technology enables the creation of intricate designs and patterns, and is often employed in industries such as signage, metalworking, and electronics.

CNC Machining

CNC (Computer Numerical Control) machining involves using computer-controlled machines to cut, shape, or drill materials. It offers high precision and repeatability, and can handle a wide range of materials, including metals, plastics, and wood.

CNC machining is widely used in the production of complex parts for industries such as automotive, aerospace, and manufacturing. It enables the creation of precision components with tight tolerances and intricate geometries.

Materials and Applications

Creative fabrication encompasses a wide range of materials, each with unique properties and applications. These materials include metals, plastics, and composites, which are utilized across various industries.

Metals

Metals are renowned for their strength, durability, and malleability. Common metals used in creative fabrication include steel, aluminum, and titanium. Steel is known for its high strength and is often used in structural applications. Aluminum is lightweight and corrosion-resistant, making it suitable for aerospace and automotive industries.

Titanium is exceptionally strong and lightweight, often employed in high-performance applications.

Plastics

Plastics offer versatility, low cost, and ease of fabrication. They include thermoplastics, thermosets, and elastomers. Thermoplastics, such as polyethylene and polypropylene, can be repeatedly melted and reshaped, making them suitable for injection molding and 3D printing. Thermosets, like epoxy and polyester resins, undergo irreversible chemical changes upon curing, resulting in high strength and rigidity.

Elastomers, such as rubber and silicone, provide flexibility and shock absorption.

Composites

Composites combine different materials to achieve properties not found in individual materials. They consist of a matrix material, such as resin or metal, reinforced with fibers or particles. Composites offer high strength-to-weight ratios, stiffness, and durability. Carbon fiber-reinforced polymers (CFRPs) are commonly used in aerospace, automotive, and sports equipment due to their exceptional strength and lightweight nature.

Applications of Creative Fabrication

Creative fabrication finds applications in diverse industries, including architecture, design, and manufacturing. In architecture, it enables the creation of complex and innovative structures, such as curved roofs and intricate facades. In design, it facilitates the production of unique and functional objects, such as furniture, lighting, and sculptures.

In manufacturing, it supports the development of prototypes, custom parts, and production tools.

Design Principles: Creative Fab

Design principles are the fundamental guidelines that guide the creative fabrication process, ensuring the creation of functional, aesthetically pleasing, and innovative products. They provide a framework for designers to approach the design process systematically, considering various factors that influence the outcome.

These principles encompass a wide range of considerations, including the form, function, and aesthetics of the product. Form refers to the physical shape and structure of the product, while function pertains to its intended purpose and how it meets user needs.

Aesthetics involves the visual appeal and sensory experience of the product, including factors like color, texture, and ergonomics.

Form

The form of a product is crucial for its functionality and aesthetics. Designers must carefully consider the materials used, the manufacturing processes involved, and the intended use of the product to create a form that is both practical and visually appealing.

For instance, a product designed for outdoor use may require a durable material that can withstand the elements, while a product intended for indoor use may prioritize aesthetics and comfort.

Function

The function of a product is paramount in the design process. Designers must thoroughly understand the user needs and the intended purpose of the product to create a design that effectively meets those requirements. This involves considering factors such as ergonomics, usability, and safety.

For example, a medical device must be designed to be easy to use and minimize the risk of errors, while a consumer product may prioritize convenience and user-friendliness.

Aesthetics

Aesthetics play a significant role in the appeal and desirability of a product. Designers must consider factors such as color, texture, and shape to create a product that is visually pleasing and符合潮流. Aesthetics can also influence the perceived value and quality of a product, making it an important consideration in the design process.

For instance, a luxury product may use high-quality materials and a sophisticated design to convey a sense of exclusivity and desirability.

Workflow and Collaboration

The creative fabrication process typically involves a collaborative workflow among designers, engineers, and fabricators. Designers conceptualize the initial design, considering the functional and aesthetic aspects. Engineers then translate the design into technical specifications, ensuring structural integrity and manufacturability. Fabricators bring the design to life, using specialized equipment and techniques to create the physical product.

Collaboration and Communication

Effective communication and collaboration are crucial throughout the workflow. Regular meetings, design reviews, and progress updates help align the team’s understanding and ensure the project remains on track. Clear communication channels facilitate the exchange of ideas, feedback, and problem-solving. By working together, designers, engineers, and fabricators can optimize the design, minimize errors, and ensure the project’s success.

Digital Tools and Software

Digital tools and software are essential for streamlining the creative fabrication process. They enable designers and fabricators to create complex designs, generate accurate prototypes, and efficiently manage production processes.

Computer-aided design (CAD) software is used to create 3D models of objects. These models can be used to visualize designs, perform simulations, and generate toolpaths for fabrication. CAM software is used to convert CAD models into instructions for CNC machines, which are used to fabricate objects.

3D Modeling Software

- Rhinoceros 3D:A versatile modeling software popular in architecture, industrial design, and product design.

- SolidWorks:A parametric modeling software widely used in mechanical engineering and product development.

- Fusion 360:A cloud-based modeling software that combines CAD, CAM, and CAE capabilities.

CAM Software, Creative fab

- Mastercam:A popular CAM software used in various industries, including aerospace, automotive, and mold making.

- Siemens NX CAM:A comprehensive CAM software that offers advanced features for complex machining operations.

- HSMWorks:A CAM software known for its high-speed machining capabilities.

Simulation Software

- ANSYS:A powerful simulation software used to analyze structural integrity, fluid dynamics, and electromagnetic fields.

- COMSOL Multiphysics:A simulation software that allows users to model and analyze coupled physical phenomena.

- Abaqus:A finite element analysis software used for complex engineering simulations.

Sustainability and Environmental Impact

In the realm of creative fabrication, sustainability plays a pivotal role. As designers and fabricators, we have a responsibility to minimize our environmental impact while creating innovative and functional products.

To achieve sustainability in creative fabrication, we must adopt practices that reduce waste, conserve energy, and promote the use of recycled and sustainable materials. By implementing these strategies, we can create products that are not only aesthetically pleasing but also environmentally conscious.

Methods to Reduce Waste and Minimize Environmental Impact

- Utilize digital fabrication techniques to minimize material waste and optimize cutting processes.

- Implement recycling programs to divert waste from landfills and conserve resources.

- Explore the use of biodegradable and compostable materials to reduce the environmental footprint of products.

- Design products with modular components and standardized parts to facilitate easy repair and reduce waste.

Incorporation of Recycled and Sustainable Materials

Incorporating recycled and sustainable materials into creative fabrication is crucial for reducing our environmental impact. These materials offer numerous benefits, including:

- Conserving natural resources and reducing waste.

- Lowering greenhouse gas emissions associated with material production.

- Creating products that are more environmentally friendly and sustainable.

Examples of recycled and sustainable materials commonly used in creative fabrication include:

- Recycled plastics and metals

- Sustainable wood and bamboo

- Biodegradable and compostable polymers

Strategies to Reduce Energy Consumption During Fabrication Processes

Reducing energy consumption during fabrication processes is essential for minimizing our environmental impact. This can be achieved through:

- Utilizing energy-efficient equipment and machinery.

- Optimizing production processes to reduce energy waste.

- Implementing renewable energy sources, such as solar and wind power, to power fabrication facilities.

Design Principles that Promote Longevity and Recyclability of Products

Incorporating design principles that promote longevity and recyclability is crucial for creating sustainable products. These principles include:

- Designing products with durable and repairable components.

- Using materials that are easily recyclable or biodegradable.

- Designing products that can be easily disassembled and reassembled.

Environmental Regulations and Standards Applicable to Creative Fabrication

It is important to be aware of the environmental regulations and standards applicable to creative fabrication. These regulations vary depending on the location and industry, but generally include:

- Waste management and disposal regulations

- Air and water pollution control regulations

- Energy efficiency standards

By adhering to these regulations and standards, we can ensure that our creative fabrication practices are environmentally responsible and compliant with the law.

Innovation and Future Trends

The creative fabrication industry is constantly evolving, with new trends and innovations emerging all the time. These trends are shaping the future of the industry, and they are having a major impact on the way that creative fabrication is used in a wide range of applications.

One of the most important trends in creative fabrication is the development of new technologies and materials. These technologies and materials are making it possible to create new and innovative products that were previously impossible to manufacture. For example, 3D printing is now being used to create complex and intricate objects that would be difficult or impossible to make using traditional manufacturing methods.

Creative Fab is all about finding unique and creative ways to express yourself, whether it’s through art, fashion, or even food. One great way to get creative in the kitchen is to make your own snacks. And what could be more creative than creative snacks strawberry yogurt pretzels ?

These sweet and salty treats are perfect for a quick snack or a fun party appetizer. And the best part is, they’re super easy to make! So get creative and have some fun in the kitchen with Creative Fab.

Role of AI and Machine Learning

Artificial intelligence (AI) and machine learning are also playing a major role in the future of creative fabrication. These technologies are being used to automate and enhance creative fabrication processes, making them more efficient and productive. For example, AI is being used to design new products, optimize manufacturing processes, and inspect finished products.

Sustainable and Eco-friendly Practices

Sustainability is another important trend in creative fabrication. As the world becomes increasingly aware of the environmental impact of manufacturing, there is a growing demand for sustainable and eco-friendly practices in creative fabrication. This includes using recycled materials, reducing energy consumption, and minimizing waste.

Impact on Skills and Training

The rapid pace of innovation in creative fabrication is having a major impact on the skills and training required for creative fabrication professionals. In order to keep up with the latest trends, professionals need to be constantly learning and developing new skills.

This includes learning about new technologies, materials, and software, as well as developing new design and engineering skills.

Innovative Projects and Initiatives

There are a number of innovative projects and initiatives that are demonstrating the potential of these trends. For example, the MIT Media Lab is developing a new type of 3D printer that can print objects from a variety of materials, including metal and ceramic.

This printer has the potential to revolutionize the way that products are manufactured.

Another example is the Fab Foundation, a non-profit organization that is working to make digital fabrication accessible to everyone. The Fab Foundation is providing training and resources to schools, libraries, and community centers around the world, so that people can learn about and use digital fabrication technologies.

– Provide visual examples of creative fabrication projects, showcasing innovative designs and applications.

Creative fabrication projects are characterized by their innovative use of materials, technologies, and processes to create unique and functional objects. These projects often push the boundaries of what is possible, and can be used to create everything from furniture and fashion to architecture and medical devices.

To provide a better understanding of the capabilities of creative fabrication, we have compiled a gallery of visual examples of some of the most innovative and groundbreaking projects from around the world. These projects showcase a wide range of designs and applications, and are sure to inspire you to think outside the box when it comes to your own creative projects.

Furniture

Creative fabrication techniques are being used to create innovative and stylish furniture pieces that are both functional and visually appealing. These pieces often feature unique designs and are made from a variety of materials, including wood, metal, plastic, and even recycled materials.

- Project:3D-printed chair Description:This chair was designed using 3D modeling software and then printed using a 3D printer. The chair is made from a lightweight and durable plastic, and features a unique design that is both comfortable and stylish.

- Project:Parametric furniture Description:Parametric furniture is designed using computer software that allows the user to control the shape and size of the piece. This type of furniture is often made from wood or metal, and can be customized to fit the specific needs of the user.

Educational Programs and Training Opportunities in Creative Fabrication

Creative fabrication is a rapidly growing field that offers exciting opportunities for those interested in design, engineering, and technology. There are a variety of educational programs and training opportunities available to help you develop the skills and knowledge you need to succeed in this field.

Online Courses and Workshops

Online courses and workshops are a great way to learn about creative fabrication from the comfort of your own home. These programs typically cover a wide range of topics, including design principles, fabrication techniques, and software applications.Some popular online courses and workshops include:* Creative Fabrication Fundamentals from Autodesk

- Digital Fabrication for Beginners from Coursera

- 3D Printing for Creative Fabrication from Udemy

Degree Programs

If you are interested in a more comprehensive education in creative fabrication, you can pursue a degree program at a college or university. These programs typically take four years to complete and cover a wide range of topics, including design, engineering, and fabrication techniques.Some popular degree programs in creative fabrication include:* Bachelor of Science in Creative Fabrication from the University of California, Berkeley

- Bachelor of Arts in Digital Fabrication from the Rhode Island School of Design

- Master of Science in Creative Fabrication from the Massachusetts Institute of Technology

Skills and Knowledge Required to Succeed in Creative Fabrication

To succeed in the field of creative fabrication, you will need a strong foundation in design, engineering, and fabrication techniques. You should also be proficient in using digital tools and software applications.Some of the key skills and knowledge required to succeed in creative fabrication include:* Design principles and aesthetics

- Engineering principles and materials science

- Fabrication techniques, such as 3D printing, laser cutting, and CNC machining

- Digital tools and software applications, such as CAD, CAM, and FEA

Successful Individuals in the Field of Creative Fabrication

There are many successful individuals in the field of creative fabrication who have made significant contributions to the industry. Some of these individuals include:* Neri Oxman, an architect and designer who is known for her work in digital fabrication and biomimetics

- Michael Hansmeyer, an artist and designer who is known for his work in 3D printing and generative design

- Joris Laarman, a designer and architect who is known for his work in robotics and digital fabrication

Resources for Finding Educational Programs and Training Opportunities in Creative Fabrication

There are a number of resources available to help you find educational programs and training opportunities in creative fabrication. Some of these resources include:* The Creative Fabrication Network

- The Fab Foundation

- The National Science Foundation

- The American Society of Mechanical Engineers

Table Summarizing Educational Programs and Training Opportunities in Creative Fabrication

The following table summarizes the different types of educational programs and training opportunities available in creative fabrication, including their duration, cost, and location.| Program Type | Duration | Cost | Location ||—|—|—|—|| Online Courses and Workshops | 1-12 weeks | $0-$500 | Online || Degree Programs | 4 years | $20,000-$80,000 | College or university || Certificate Programs | 1-2 years | $5,000-$20,000 | College or university || Apprenticeships | 1-4 years | $0-$20,000 | Fabrication shop |

Frequently Asked Questions about Educational Programs and Training Opportunities in Creative Fabrication

Here are some frequently asked questions about educational programs and training opportunities in creative fabrication:* What are the prerequisites for an educational program in creative fabrication?

- What are the career opportunities for graduates of an educational program in creative fabrication?

- How can I find an educational program in creative fabrication that is right for me?

Tips for Choosing the Right Educational Program or Training Opportunity for Your Needs

Here are some tips for choosing the right educational program or training opportunity for your needs:* Consider your career goals. What type of job do you want to have in the field of creative fabrication?

- Research different educational programs and training opportunities. Compare their curricula, costs, and locations.

- Talk to professionals in the field of creative fabrication. Get their advice on which educational programs and training opportunities are the best.

- Make a decision that is right for you. Consider your career goals, financial situation, and learning style when making your decision.

Industry Leaders and Pioneers

The field of creative fabrication is constantly evolving, thanks to the dedication and innovation of its leading figures and organizations. These pioneers have pushed the boundaries of what’s possible with creative fabrication, and their work has had a profound impact on the industry.

One of the most influential figures in creative fabrication is Neri Oxman. Oxman is an architect and designer who has developed a new approach to design that combines digital fabrication with biological principles. Her work has been featured in museums around the world, and she has received numerous awards for her contributions to the field.

Organizations

In addition to individual pioneers, there are also a number of organizations that are leading the advancement of creative fabrication. These organizations provide resources and support to researchers and practitioners, and they help to promote the adoption of creative fabrication technologies.

- The Fab Foundationis a non-profit organization that promotes the use of digital fabrication technologies in education and research. The Fab Foundation provides resources and support to Fab Labs around the world, and it organizes the annual Fab Academy, a global educational program that teaches students how to use digital fabrication technologies.

- The Massachusetts Institute of Technology (MIT)is a leading research institution that has been at the forefront of creative fabrication for decades. MIT’s Media Lab is home to a number of research projects that are exploring the potential of creative fabrication, and MIT’s Fab Lab is one of the most well-equipped and well-used Fab Labs in the world.

Describe the different types of creative fab labs and maker spaces, including their unique capabilities and target audiences.

Creative fab labs and maker spaces are community-oriented workshops that provide access to tools, equipment, and expertise for creative production. They come in various types, each with its own unique capabilities and target audiences:

- University Fab Labs:Primarily serve students and faculty, offering advanced equipment for research and academic projects.

- Community Fab Labs:Open to the public, providing access to a wide range of tools for personal projects, entrepreneurial ventures, and community-based initiatives.

- School Fab Labs:Designed for K-12 education, fostering hands-on learning and STEM skills development.

- Corporate Fab Labs:In-house facilities for businesses, supporting product development, prototyping, and innovation.

- Independent Maker Spaces:Privately owned and operated, offering specialized equipment and a collaborative environment for makers and entrepreneurs.

Creative Fabrication in Architecture

Creative fabrication is transforming the field of architecture, enabling the design and construction of innovative and sustainable buildings and structures. This technology allows architects to explore new design possibilities, push the boundaries of construction techniques, and create personalized and responsive built environments.

Applications in Architectural Design

Creative fabrication empowers architects with advanced tools and techniques for architectural design. They can create complex and organic forms, optimize structural performance, and explore sustainable design solutions. 3D modeling software and digital fabrication techniques enable the creation of detailed designs with precise dimensions and intricate geometries.

Construction and Assembly

Creative fabrication streamlines the construction process, allowing for faster and more efficient building assembly. Robotic assembly and automated fabrication techniques reduce labor costs and improve accuracy, while prefabricated components enable modular construction. This approach reduces construction time, minimizes waste, and enhances the quality of the built environment.

Restoration and Renovation

Creative fabrication offers innovative solutions for the restoration and renovation of historic buildings. 3D scanning and digital modeling techniques enable the precise replication of architectural details, preserving the integrity of the original design. Advanced fabrication methods allow for the creation of custom-made components and the integration of sustainable materials, enhancing the building’s performance and extending its lifespan.

Advantages and Challenges

While creative fabrication offers numerous advantages, it also presents challenges that need to be considered. The cost of advanced fabrication equipment and materials can be a limiting factor, especially for smaller-scale projects. Additionally, the integration of digital fabrication techniques requires specialized knowledge and skills, which may not be readily available in all architectural firms.

Potential Future Applications

Creative fabrication holds immense potential for the future of architecture. It will enable the creation of sustainable and responsive buildings that adapt to changing environmental conditions and user needs. The integration of sensors and actuators into fabricated structures will allow for real-time monitoring and control, optimizing energy efficiency and occupant comfort.

Architectural Projects Using Creative Fabrication

Numerous architectural projects have successfully employed creative fabrication techniques, showcasing the transformative power of this technology. The Burj Khalifa, the world’s tallest building, features a complex façade made of prefabricated aluminum panels, manufactured using advanced fabrication techniques. The Beijing National Stadium, also known as the “Bird’s Nest,” is an iconic structure that utilizes a steel framework fabricated using robotic assembly.

Creative Fabrication in Art and Design

Creative fabrication is revolutionizing the art and design industries, providing artists and designers with unprecedented tools and techniques to create unique and expressive works.

Artistic Possibilities

Fabrication technologies allow artists to explore new forms, textures, and materials, pushing the boundaries of traditional art practices. From 3D printing sculptures to laser cutting intricate patterns, fabrication technologies enable artists to create works that are both visually stunning and conceptually challenging.

Design Innovation

In design, fabrication technologies are used to create functional and aesthetically pleasing objects, from furniture and lighting to architectural structures. By combining digital design tools with advanced fabrication techniques, designers can optimize designs for performance, durability, and sustainability.

Impact on the Creative Process

Fabrication technologies have transformed the creative process, allowing artists and designers to iterate and refine their ideas more quickly and efficiently. Digital tools enable them to experiment with different design concepts and materials, while fabrication technologies provide the means to bring their designs to life.

Examples

- 3D-printed sculptures by Neri Oxman explore the intersection of art and biology.

- Laser-cut metalwork by Zaha Hadid Architects creates complex and fluid architectural forms.

- Digitally fabricated furniture by Ross Lovegrove combines organic shapes with functional design.

Fabrication Technologies

| Technology | Advantages | Disadvantages |

|---|---|---|

| 3D Printing | – Rapid prototyping

| – Limited material selection

|

| Laser Cutting | – Precision cutting

| – Can produce fumes

|

| CNC Machining | – High accuracy

| – Slow process

|

Future Trends

The future of creative fabrication is bright, with emerging technologies such as AI and generative design promising to further expand the possibilities for artistic expression and design innovation. As fabrication technologies become more accessible and affordable, they will continue to empower artists and designers to create works that push the boundaries of creativity and inspire audiences worldwide.

Question & Answer Hub

What is creative fabrication?

Creative fabrication is the process of using advanced technologies, such as 3D printing, laser cutting, and CNC machining, to create physical objects from digital designs.

What are the benefits of creative fabrication?

Creative fabrication offers numerous benefits, including increased design freedom, faster prototyping, reduced production costs, and the ability to create complex geometries.

What industries use creative fabrication?

Creative fabrication finds applications in a wide range of industries, including architecture, design, manufacturing, healthcare, and aerospace.

What skills are needed for creative fabrication?

Individuals working in creative fabrication typically have a background in design, engineering, or fabrication techniques.